PRODUCTS INDUSTRY SOLUTION 4.0

PRODUCTS INDUSTRY SOLUTION 4.0

Manufacturing Execution System, MES

Producción, calidad, planificación, mantenimiento y mucho más...

Plataforma M.E.S. de última generación, que le permitirá el control y la gestión global de la información de todas sus plantas de producción y la perfecta integración de los datos con su ERP, solución especializada en recopilación de datos de control de producción, calidad y mantenimiento.

Los productos se agrupan en módulos funcionales que pueden trabajar independientes, con integración directa con los ERP, y con conexión directa a las señales de máquinas y de proceso que sean necesarias. La suite de productos engloba la mayor parte de las necesidades de control de planta con distintas características:

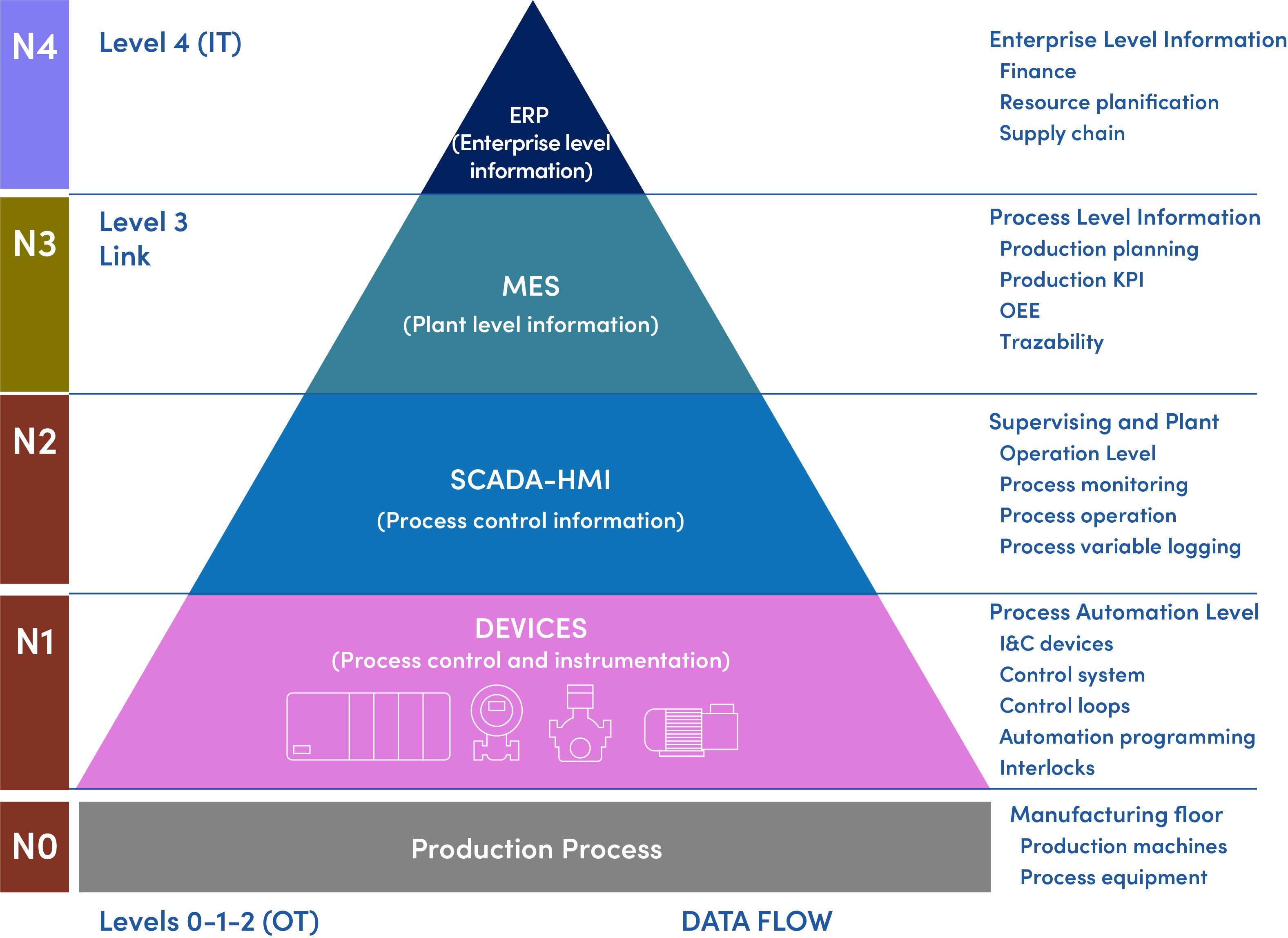

Integración vertical (OT con IT) ISA 95

Módulos del sistema MES

Control de producción

Calidad y trazabilidad

Monitoreo de producción

Dashboards

Planificación de ordenes de fabricación

Gestión de utilities

Producción

Quality

Maintenance

Traceability

Soluciones MES

Producción OEE

El control y la gestión global de sus fábricas, totalmente integrado con su ERP, la solución utiliza la captura automática de datos de cualquier máquina o sensor para obtener datos objetivos, fiables y en tiempo real.

Eficiencia energética

Un sistema simple de registro de parámetros o variables que varían en el tiempo. El sistema se comunica con cualquier dispositivo industrial que tenga una salida de comunicaciones o una salida en tensión o corriente.

Mantenimiento predictivo

Evalúa el estado de la maquinaria y recomienda intervenir o no en función de su estado, lo cual produce grandes ahorros.

Trazabilidad

Permite la gestión de los lotes de fabricación, de materias primas, semielaborado y producto final.

Módulo Reportes

Centraliza la información para una estructura sencilla, crear pantallas y reportes dinámicos en base a las necesidades del cliente.

Contenido:

Facilita el diseño de la consulta proporcionando información visual de tablas (y sus columnas) de la base de datos, pueden arrastrar las tablas deseadas a la parte central donde se deben activar las columnas deseadas.

Calidad

Sistema de gestión de calidad que le permitirá tener un control fiable y rápido de toda la información en su departamento.

Características

Beneficios

Compatible en cualquier tipo de dispositivo

Monitores

Tablet

Smartphones