INDUSTRIAS ALIMENTOS Y BEBIDAS

INDUSTRIAS ALIMENTOS Y BEBIDAS

Eficiencia de procesos y ahorros en energéticos.

El punto de partida para la eficiencia de procesos es un análisis inicial de la situación actual para determinar aquellas áreas en las que generando mejoras logremos ahorros energéticos como pueden ser: calderas, compresores, consumo de agua en general, consumo de combustibles, consumo eléctrico, entre otros.

La norma ISO 50001 representa las más recientes mejores prácticas en gestión de la energía a nivel internacional, está basada en normas nacionales y regionales existentes y ha sustituido a la norma EN 16001 desde 2012.

Beneficios de la norma de gestión energética:

Soluciones para ahorro energético:

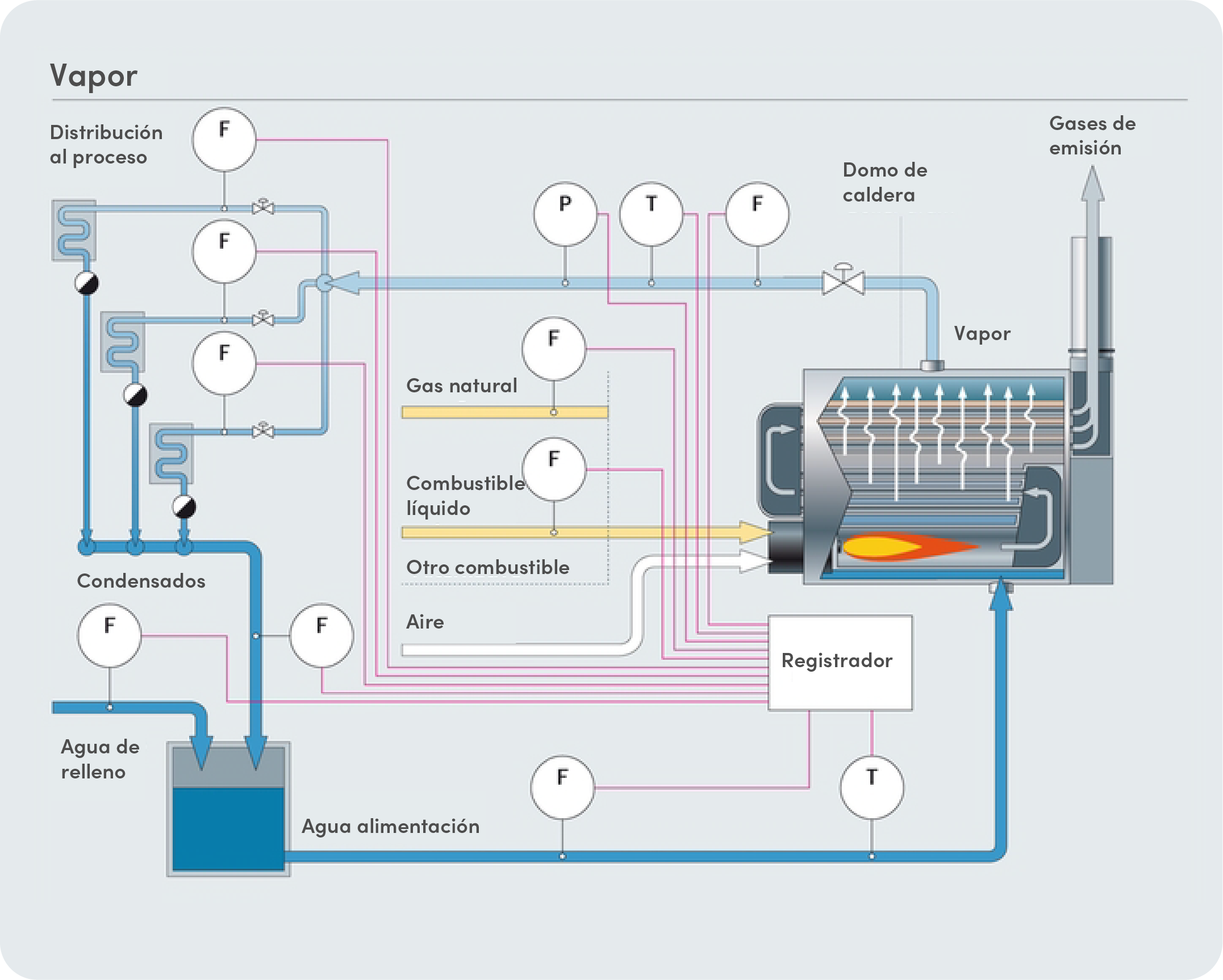

Eficiencia en calderas

Ya sea para determinar el rendimiento actual de sus equipos de caldera existente, optimizar la operación de planta o evaluar los consumos de gas de combustión, puede confiar en nuestra experiencia y conocimiento de la industria.

Mejora del control de calderas y de la seguridad de planta mediante las soluciones de medición y monitorización avanzada. Eficiencia a través del cumplimiento y del coste por unidad de consumo.

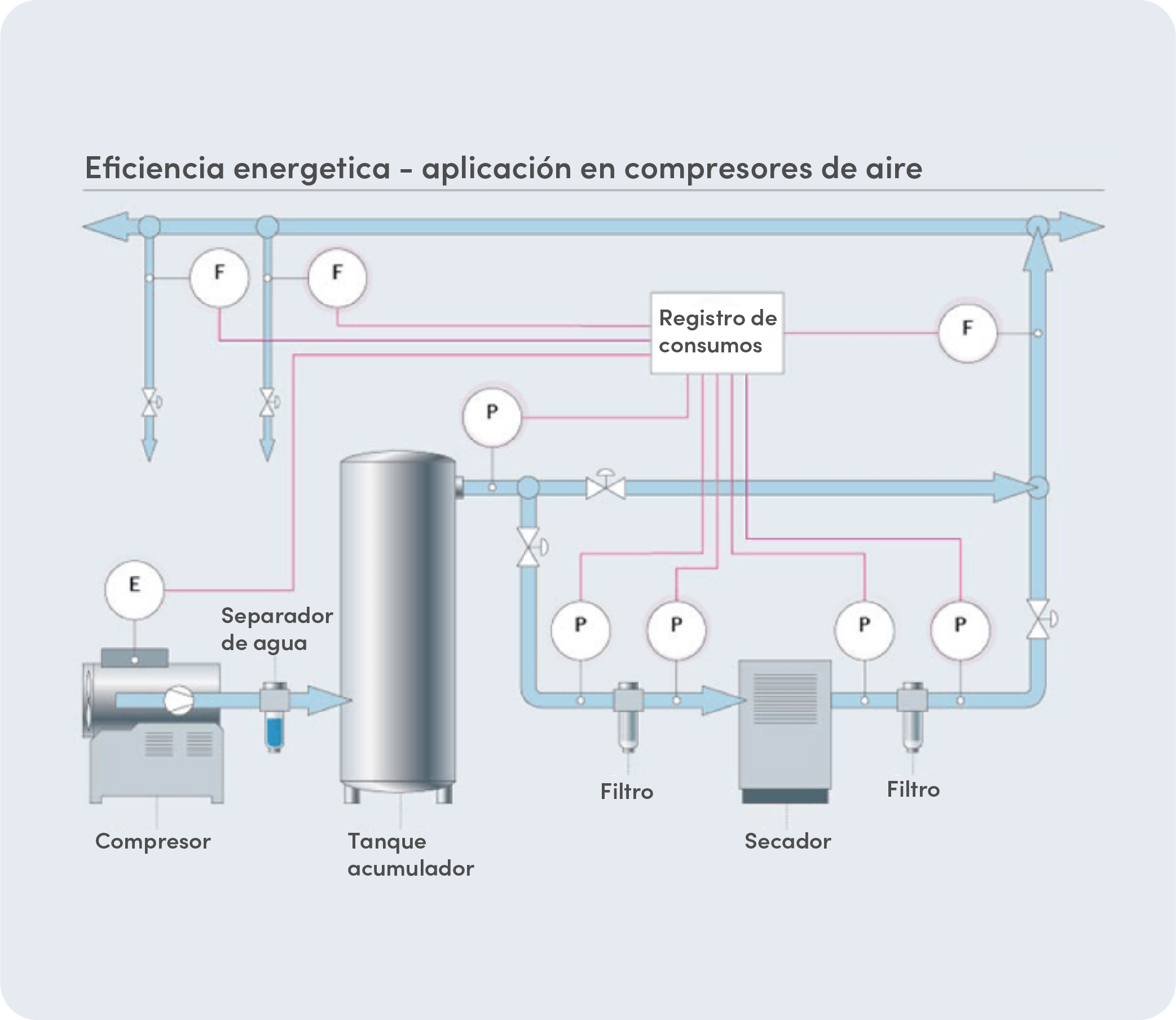

Eficiencia de compresores

Los sistemas de aire comprimido los constituyen redes de tubería neumática que recorren toda la planta hasta las estaciones de producción, en todos estos trayectos y en los centros donde se consume el aire comprimido suelen existir microfugas y operaciones no eficientes.

Es importante instalar una red de medición de aire comprimido por los diferentes ramales de planta y generar KPI’s como gráficos de consumo que indiquen a los operadores y niveles de supervisión consumos fuera de producción e incrementos en consumo con los que podemos tomar decisiones muy asertivas de eficiencia.

Ventajas del sistema:

Medidores de aire comprimido tipo térmico

Desempeño de compresor y reporte de operación

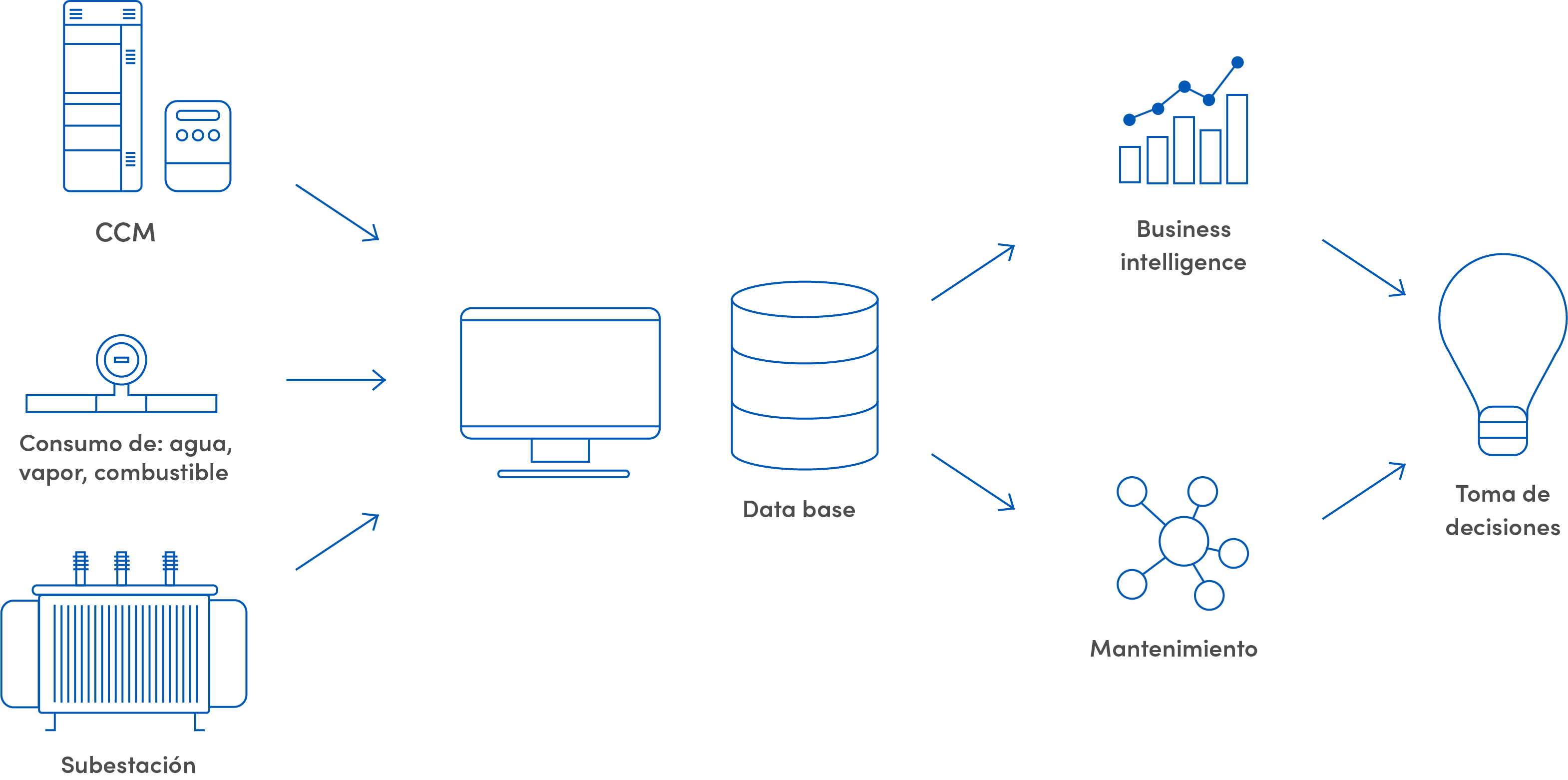

Consumo energético de planta

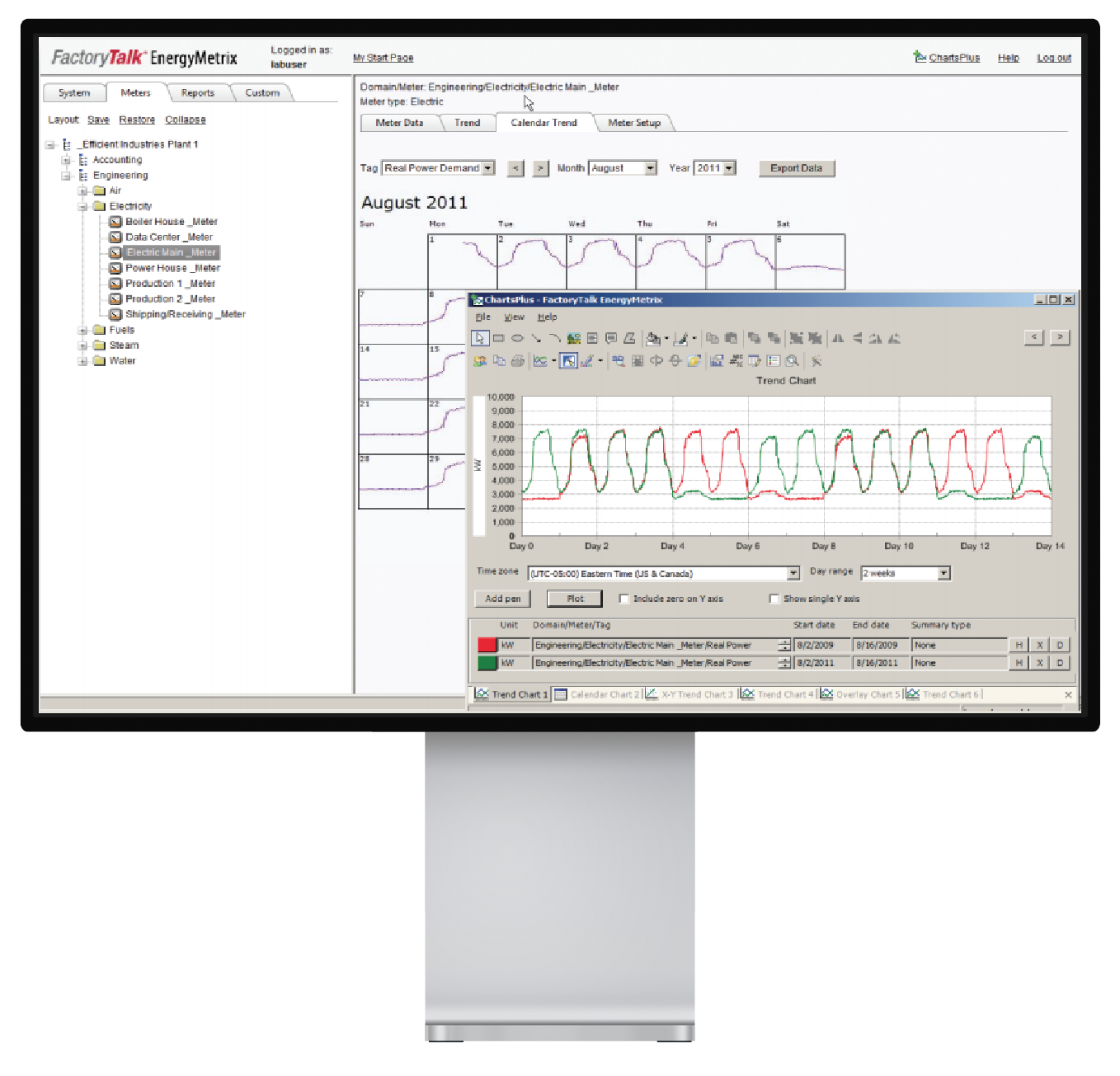

El sistema de consumo energético de planta tiene como objetivo monitorear y registrar todas aquellas áreas relevantes de consumo de planta en forma distribuida de los diferentes energéticos y agua; con esta información y la producción de planta generamos reportes y gráficos de índices de producción y energía.

Reporte de consumo energético

12.01.11.png)

Consumo eléctrico

Consumo de vapor