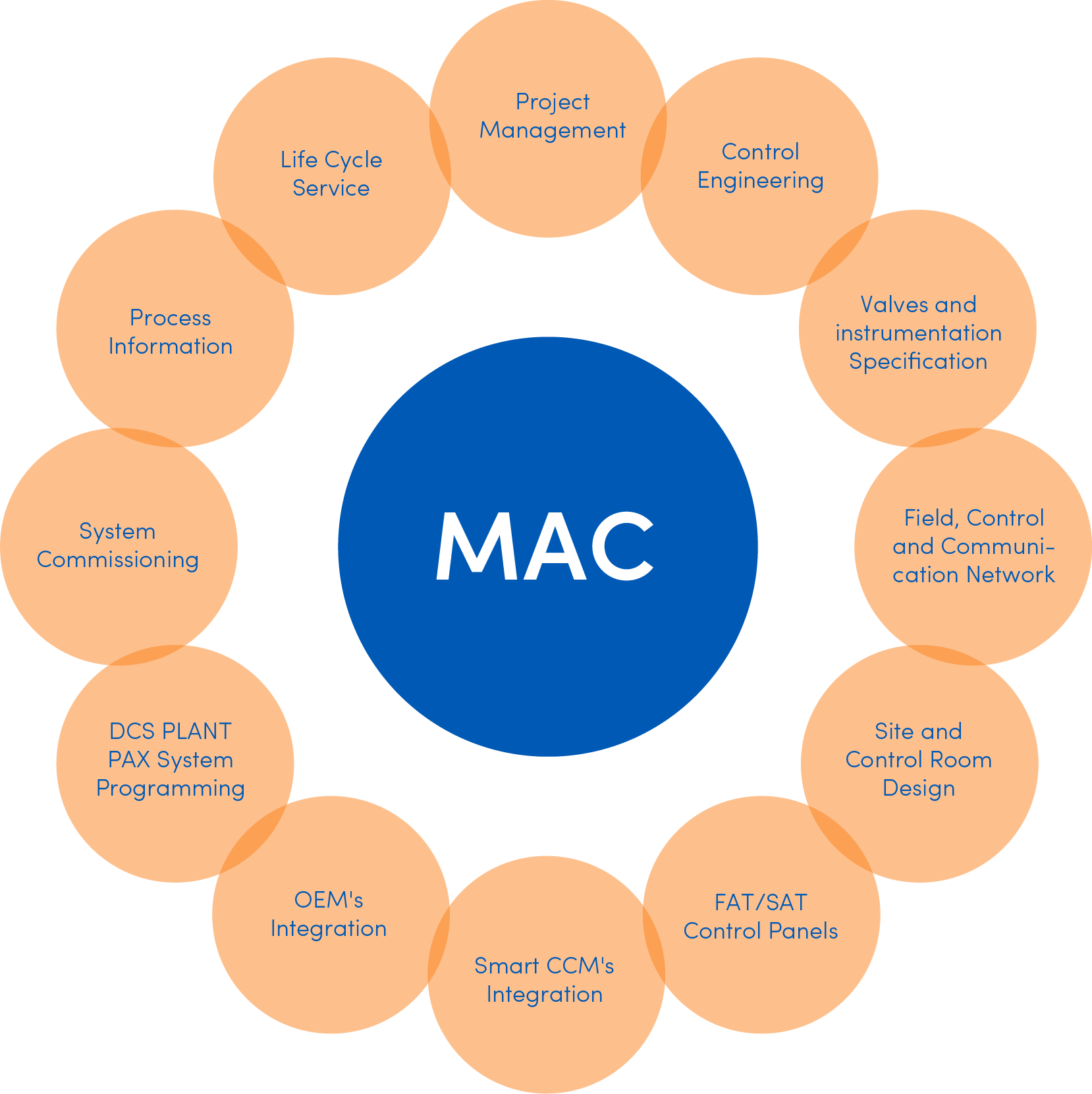

Main Automation Contractor, MAC

La complejidad de los proyectos de tecnologia requiere empresas altamente especializadas y con las capacidades para realizarlos. Los proyectos de plantas nuevas o ampliaciones incluyen sistemas de control, automatización e instrumentación de amplio alcance donde se requiere una empresa como ECN Automation para gestionar e implementar bajo la figura de Main Automation Contractor (MAC) interactuando con EPC, OEMs, plataformas de tecnología de control, comunicación e información.

El rol del MAC

Main Automation Contractor (MAC) services

Competencias y habilidades técnicas que acreditan a ECN Automation como MAC

Lo que hace que el MAC sea figura indispensable en un proyecto de automatización

Administración del alcance de Instrumentación y Control del proyecto

Definir el estándar de arquitectura de control y líneas de Instrumentación.

Desarrollo de la Ingeniería de Instrumentación y Control del Proyecto

Soporte en procuración de equipamiento del sistema de Control e Instrumentación

Diseño y programación de estrategias de control de toda la planta.

Project Done®

Project Done® es la metodología creada por ECN Automation para la gestión de proyectos basado en el resultado de proyectos exitosos de la organización así cómo en las mejores prácticas del Project Management Institute (PMI) y del American National Standard Institute (ANSI), cuenta también con el cumplimiento de los requisitos del Control System Integrators association (CSIa).