INDUSTRIAS CUIDADO DE LA SALUD

INDUSTRIAS CUIDADO DE LA SALUD

Calidad en aguas purificada (PW) y agua para inyección (WFI).

El agua purificada (PW) es utilizada como materia prima para la elaboración de alimentos, cosméticos y medicamentos de administración oral (comprimidos, jarabes, encapsulados), además de ser utilizada para la limpieza de líneas de producción.

El agua de calidad inyectable (WFI) es utilizada en la industria farmacéutica para la elaboración de medicamentos parenterales (oftálmicos, subcutáneos, intramusculares e intravenosos), además de ser utilizada en la limpieza de líneas de producción asociadas a dichos productos.

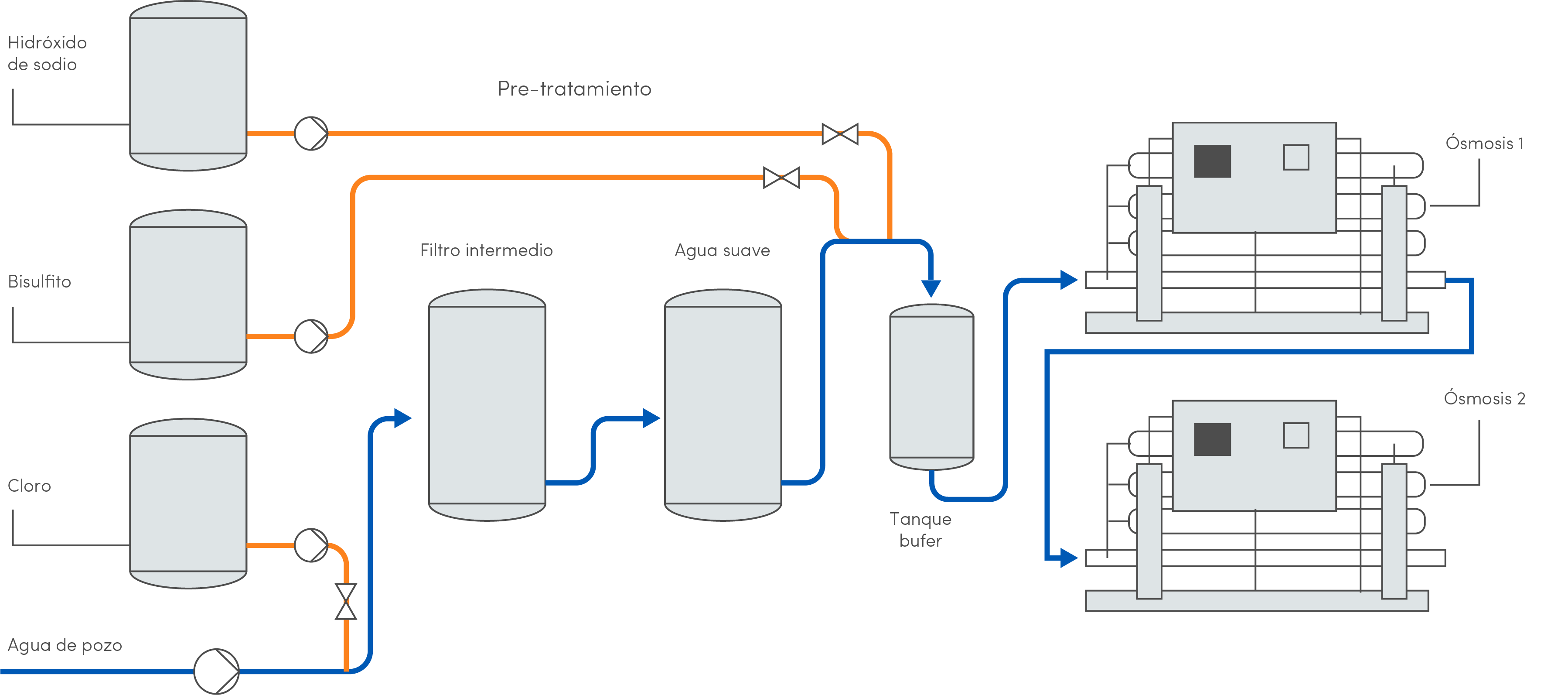

Agua purificada (PW)

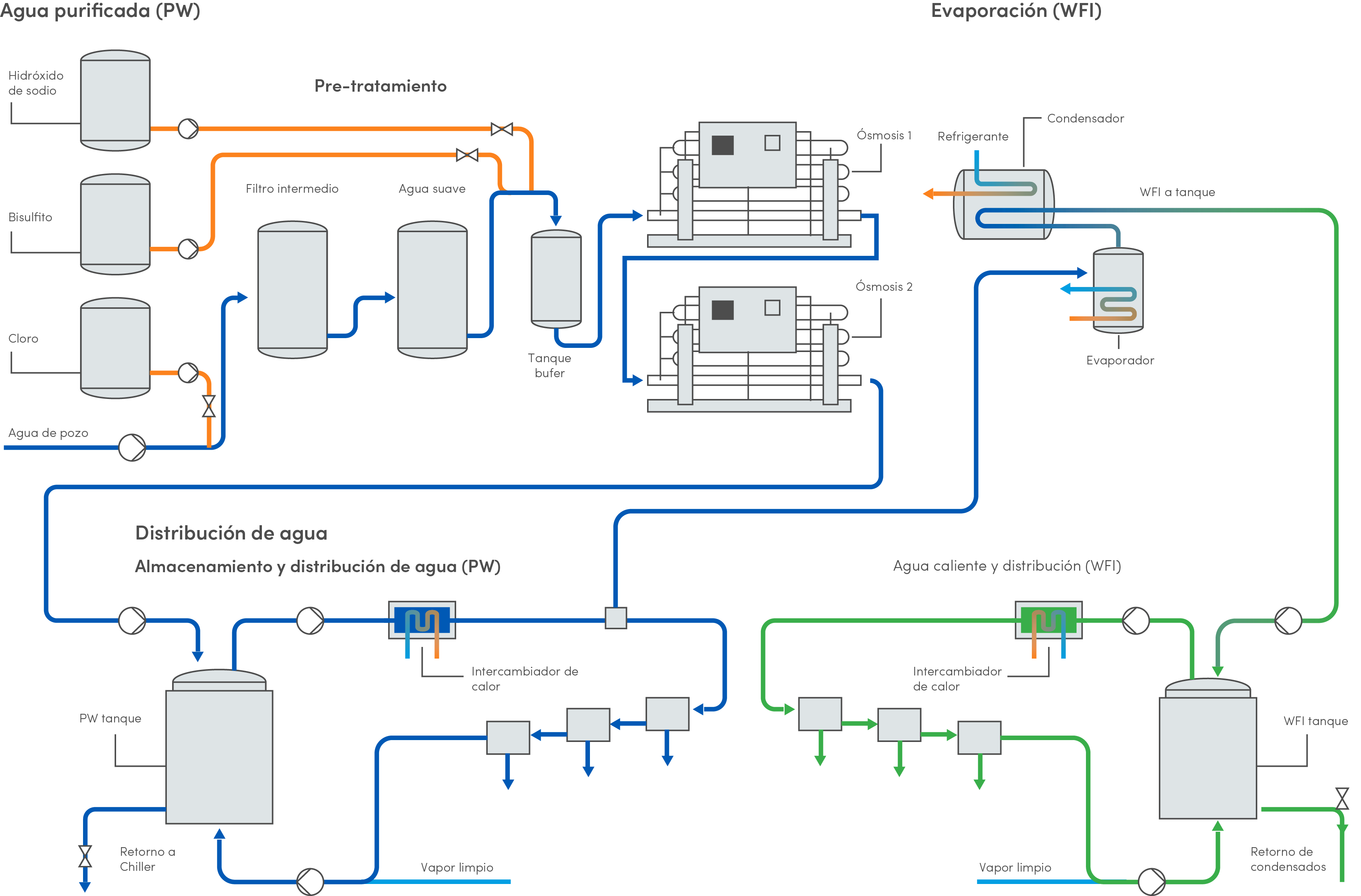

En una primera fase de pretratamiento, se procesa un agua potable de alimentación para desinfectarla, eliminar partículas y materia orgánica disueltas, y quitarle dureza. Posteriormente, se aplica un tratamiento final para reducir la carga microbiana, generalmente mediante ósmosis inversa y posterior aplicación de luz ultravioleta.

Purificación de agua y distribución

Agua para inyectables (WFI)

El agua de calidad inyectable (WFI) es utilizada en la industria farmacéutica para la elaboración de medicamentos parenterales (oftálmicos, subcutáneos, intramusculares e intravenosos), además de ser utilizada en la limpieza de líneas de producción asociadas a dichos productos.

Para la obtención de agua calidad inyectable, se parte como base de sistemas de tratamiento de agua purificada (PW) y se adhieren otros procesos unitarios para elevar su nivel de pureza.

Para el proceso de agua para inyectables (WFI) se obtiene mediante la condensación del vapor limpio obtenido en un generador de vapor, que es alimentado a su vez con agua purificada (PW). Se trata de un agua de la máxima pureza química, perfectamente estéril, dado que su principal uso es la preparación de soluciones inyectables.

Purificación de agua y distribución

Sistema de trazabilidad y MES

Para garantizar el correcto funcionamiento es necesario la implementación del sistema de control donde se resguarde toda la información como:

La trazabilidad proporciona las herramientas necesarias para la mejora de la gestión del departamento de calidad y de la planta.

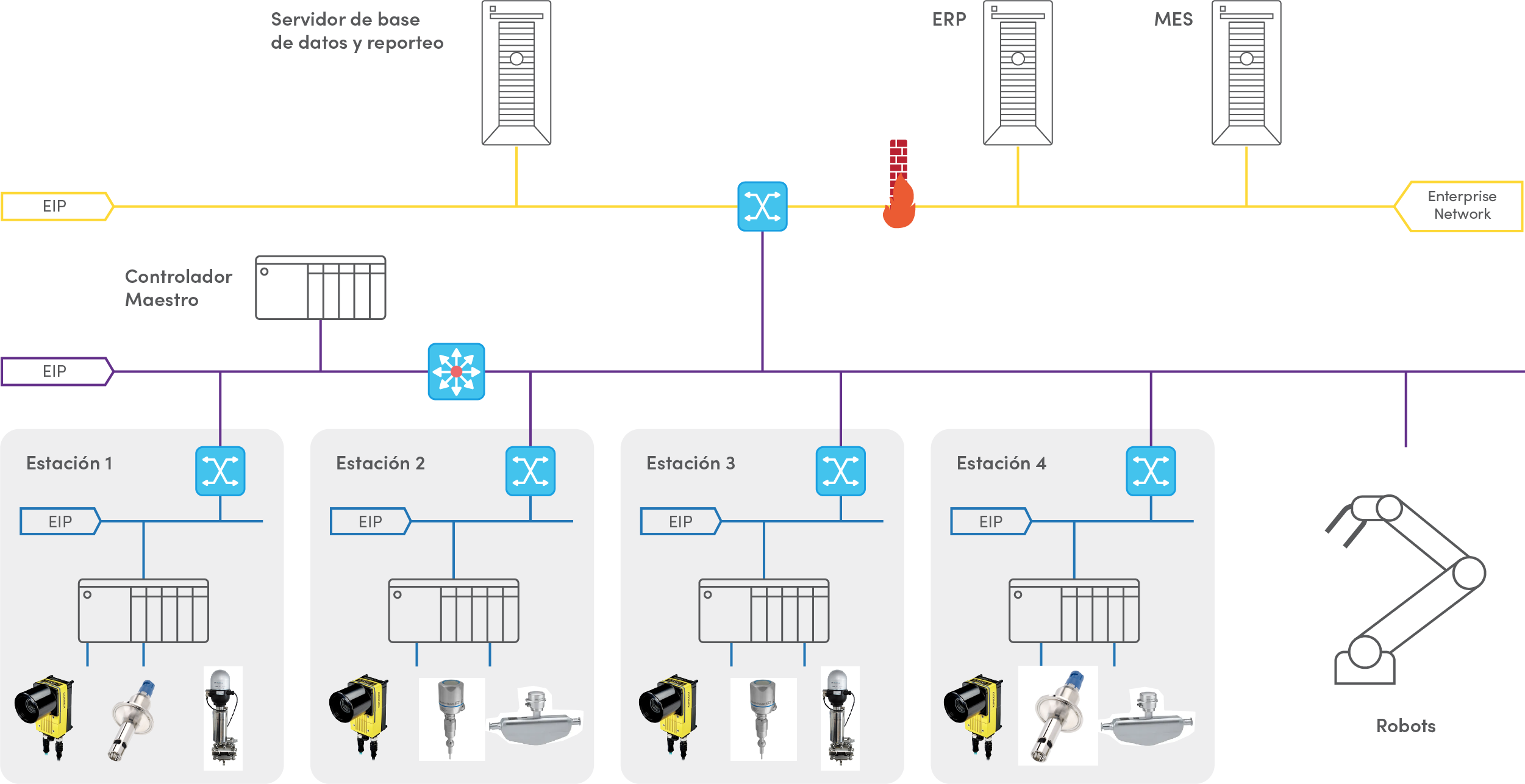

Arquitectura

La solución de arquitectura implementa scanners de código o RFID para la identificación de los componentes o productos en la línea de producción.

Nuestra solución se ajusta a las necesidades del proceso ya sea implementando lectores de código de barras o RFID para la identificación de los componentes o productos en la línea de producción.

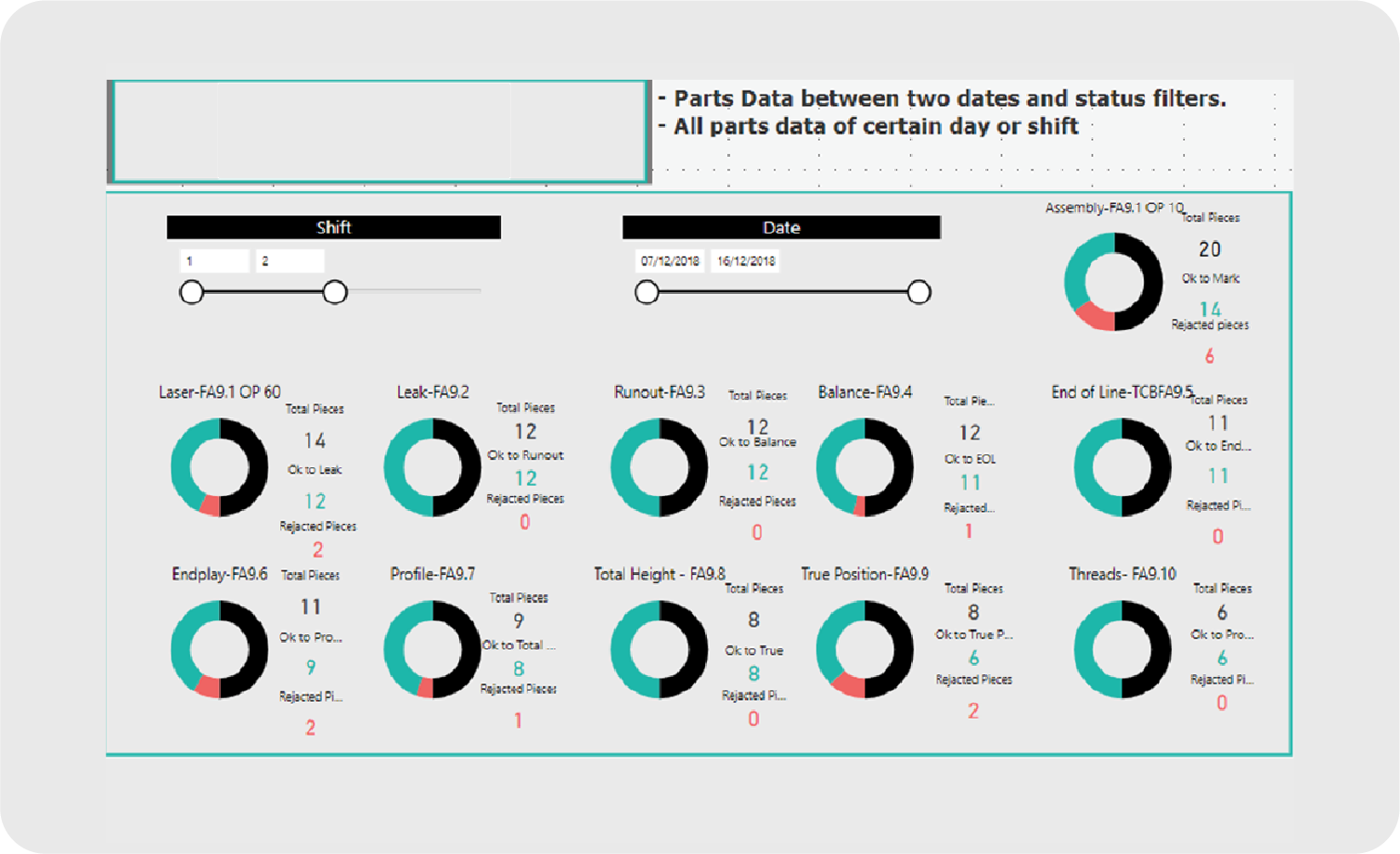

Módulo de reporteo

Se puede consultar la siguiente información.

El módulo de reportes está basado en Power Bi.

Así también se pueden realizar reportes personalizados en caso de que el cliente lo requiera.

Reporte por estación.

Sistema MES

Plataforma MES de última generación, que le permitirá el control y la gestión global de la información de todas sus plantas de producción y la perfecta integración de los datos con su ERP, solución especializada en recopilación de datos de control de producción, calidad y mantenimiento. Los productos se agrupan en módulos funcionales que pueden trabajar independientes, con integración directa con los ERP, y con conexión directa a las señales de máquinas y de proceso que sean necesarias. La suite de productos engloba la mayor parte de las necesidades de control de planta con distintas características:

Módulos del sistema MES

Control de producción

Calidad y trazabilidad

Monitoreo de producción

Dashboards

Planificación de ordenes de fabricación

Gestión de utilities