INDUSTRIAS ALIMENTOS Y BEBIDAS

INDUSTRIAS ALIMENTOS Y BEBIDAS

Seguridad de maquinaria (ISO 13849)

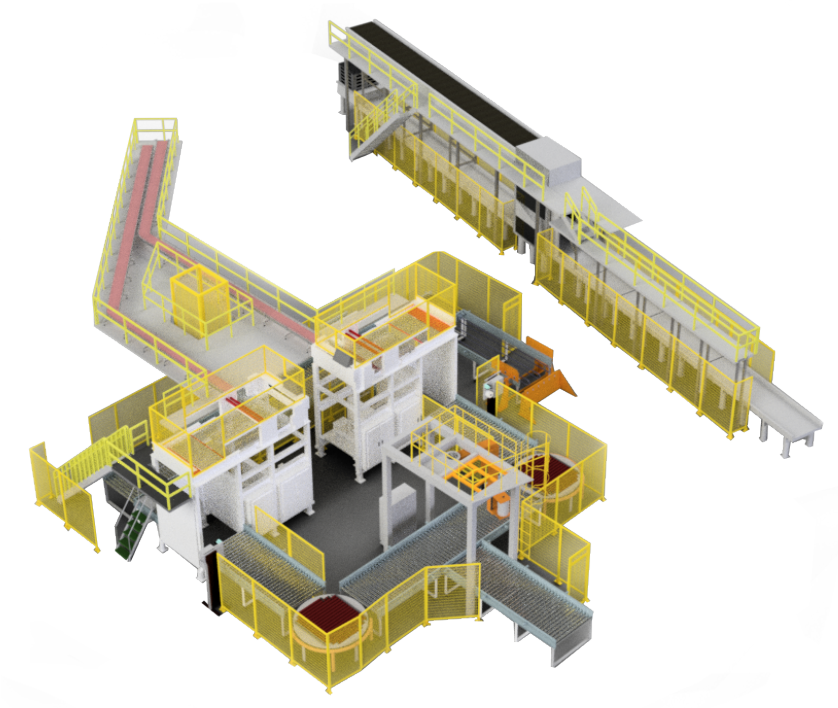

Con certificación de TÜV, ECN Automation desarrolla proyectos de seguridad de maquinaria como son paletizadoras, des paletizadora, llenadoras, lavadoras, conveyor, entre otros; entregando proyectos confiables cumpliendo con todos los requerimientos de acuerdo a la norma necesarios según análisis de riesgo de cada maquinaria.

Alcance

Aplicaciones

Proyecto de seguridad con instalación de guardas perimetrales con interlocks y cortinas de luz con controladores e instrumentación de acuerdo a ISO 13849

Normas para machine safety

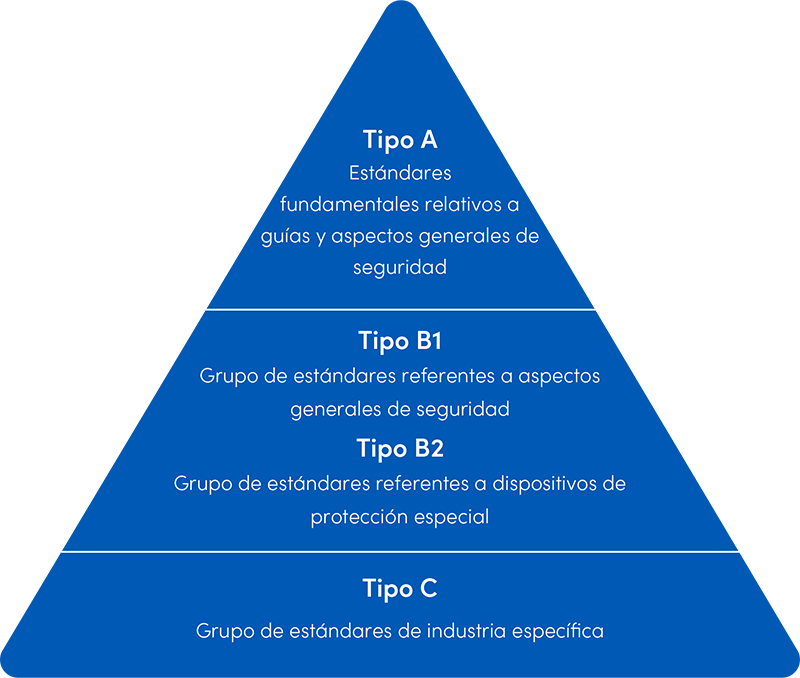

La jerarquía de los estándares de seguridad

Los estándares de seguridad están estructurados sistemática y jerárquicamente, para excluir diferentes requisitos para peligros comparables o riesgos similares o para evitar recurrencias:

Estándar de Seguridad Tipo A

Estándares fundamentales relativos a guías y aspectos generales de seguridad, referentes a todas las máquinas de una forma igual o similar p. e. evaluación de riesgos

Estándar de Seguridad Tipo B1

Grupo de estándares referentes a aspectos generales de seguridad (P.E. distancias seguras, seguridad eléctrica, velocidad de aproximación / sujeción).

Estándar de Seguridad Tipo B2

Grupo de estándares referentes a dispositivos de protección especial que pueden ser usados con máquinas (P.E. dispositivos de para de emergencia, luces de malla, dispositivos de control de dos manos).

Estándar de Seguridad Tipo C

Grupo de estándares de industria específica que establecen requerimientos definidos y medidas de seguridad.

Definiciones ISO 12100:2010

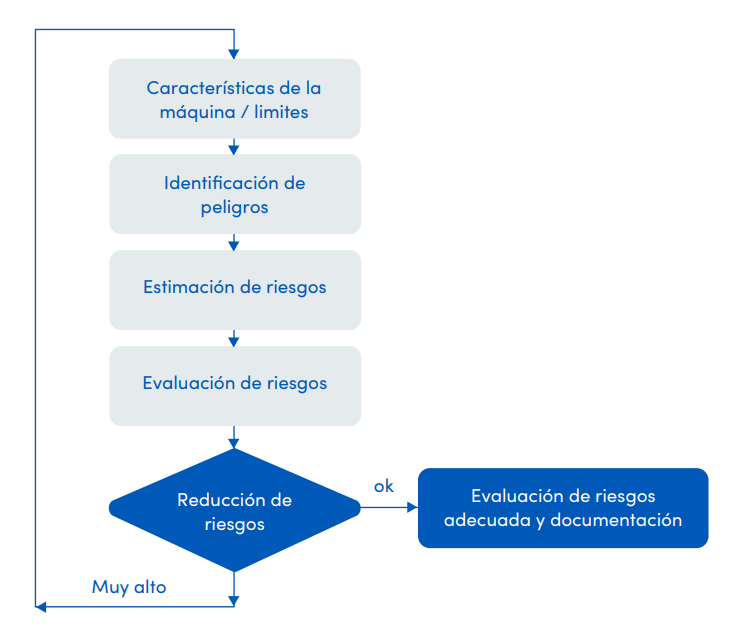

Evaluación de riesgo

Proceso global que comprende un análisis y una estimación de riesgos, típicamente un esfuerzo basado en un equipo.

Reducción adecuada del riesgo

Reducción del riesgo basado en la norma de seguridad que en criterios de aplicación de tecnología.

Estrategia para evaluación y reducción de riesgos (ISO12100)

Características de la máquina / límites

El objetivo de este paso es tener una descripción clara de:

Funciones de la maquina (basadas en la maquina)

La maquinaria puede ser descrita en términos de sus distintas partes, mecanismos o funciones basados en su construcción tales como:

El uso de la maquinaria se puede describir en términos de las tareas asociadas con el uso previsto y el mal uso razonablemente previsible de la maquinaria.