INDUSTRIAS ALIMENTOS Y BEBIDAS

INDUSTRIAS ALIMENTOS Y BEBIDAS

Clúster de válvulas sanitarias y automatización

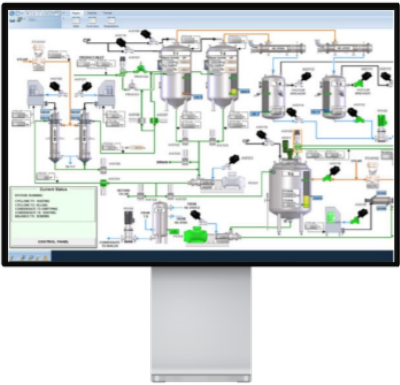

La producción de alimentos requiere de la mezcla, agregado y almacenaje de diferentes productos así mismo de la limpieza en sitio de tuberías y tanques. Para agilizar estos procesos e incrementar la producción se requiere de skids automáticos de válvulas direccionadoras antimezcla para que el fluido correcto llegue al lugar debido de manera inalterable.

En ECN Automation podemos realizar la ingeniería y fabricación de skids automáticos de válvulas direccionadoras antimezcla para la producción de alimentos.

Ingeniería de skids

17.37.43.png)

12.24.22.png)

Sistema de automatización de válvulas

Ejemplo de instalación

Componentes de un clúster de válvulas

Válvula Mix Proof

DISEÑO

D 620

Diseño antifugas, sin pérdida de producto en operación

El ciclo de limpieza incluye todos los compartimientos internos

Disco inferior tipo radial con sello RSC (Radial seal complete)

Válvula tipo simple asiento

La válvula de simple asiento único Südmo SVP proporciona la mejor base para procesos de producción eficientes y seguros debido a la amplia variedad de opciones proporcionadas por nuestro sistema modular, la facilidad de mantenimiento, la limpieza y las opciones para que las válvulas cumplan con los últimos requisitos de higiene y asépticos.

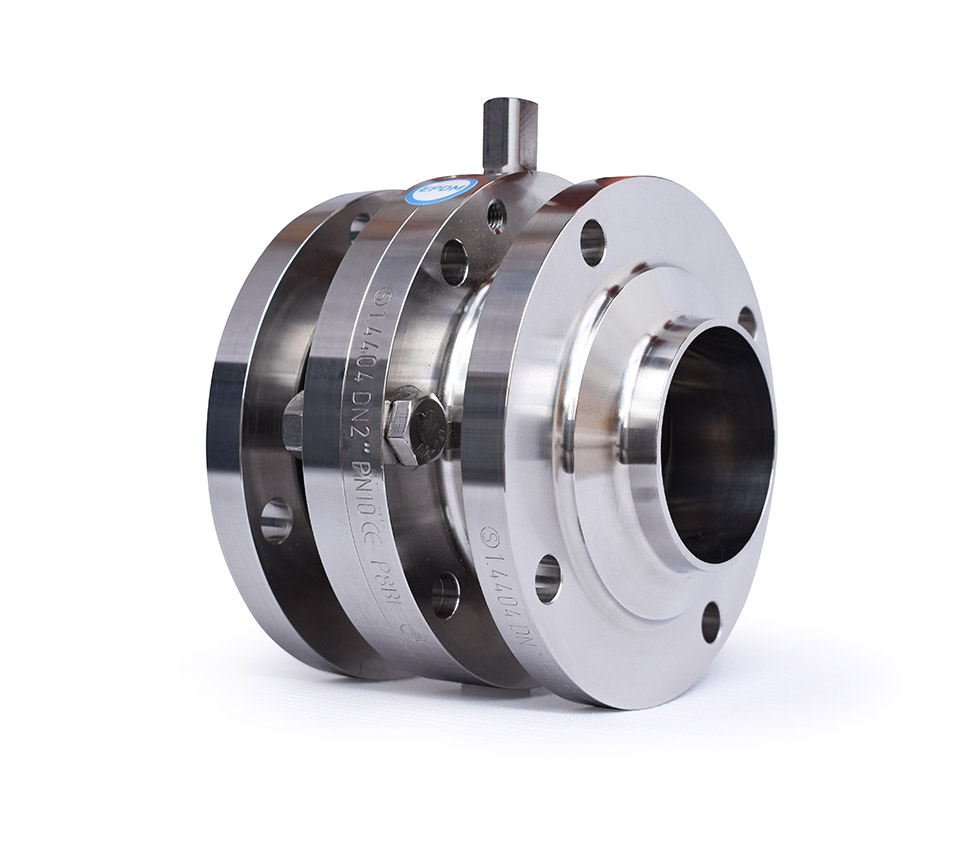

Válvulas tipo mariposa

Las válvulas de mariposa higiénicas de Pentair Südmo se utilizan principalmente en operación abierto o cerrado, ya sea manual o automático, tiene un diseño liviano y una fabricación que cumple perfectamente con estándares higiénicos, muy conveniente para la función de seccionar como parte de un clúster de válvulas.

Pentair Südmo ofrece una variedad de opciones que permiten monitorear y controlar las válvulas de cierre a través del sistema de control, incluida nuestra unidad de control IntelliTop 2.0 de última generación.