PRODUCTOS ELEMENTOS DE MEDICIÓN Y CONTROL VÁLVULAS DE CONTROL Y SECCIONADORAS

PRODUCTOS ELEMENTOS DE MEDICIÓN Y CONTROL VÁLVULAS DE CONTROL Y SECCIONADORAS

PRODUCTOS

Válvulas higiénicas

Válvulas grado higiénico manuales y automáticas para la industria alimenticia, farmacéutica y cuidado personal.

Válvulas de asiento simple

Brinda soluciones para los requisitos de procesos higiénicos más estrictos, enfocados en bebidas, alimentos, lácteos e industria farmacéutica.

DETALLES

Materiales en contacto con fluidos

Acero inoxidable 316L

Materiales sin contacto con fluidos

Acero inoxidable 304L | Acero inoxidable 304

Sellos y temperatura soportada

Agua caliente

EPDM +95°C | HNBR +95°C | FKM +80°C

Vapor

EPDM +130°C | HNBR +121°C | FKM +121°C

Agua Fría

EPDM +1 a 2°C | HNBR +1 a 2°C | FKM +1 a 2°C

Tamaños

DN 40 a DN100 1.0” a 4.0

Presión de Operación

10 bar (145 psi)

Presión de aire para control

6 bar (87 psi) a 8 bar (116 psi)

Rugosidad partes sin contacto con el fluido

Ra ≤ 0.8 µm

Rugosidad partes sin contacto con el fluido

Ra ≤ 1.6 µm | Opcional superficies pulidas y electro pulidas

Conexiones a Proceso

Conexión soldable

Operación

Actuador neumático

Válvulas de Doble Asiento o Mix Proof

Se utilizan para el aislamiento de productos y evitar que se mezclen cuando se requiera una separación segura del proceso y cuando se realiza el proceso de limpieza CIP.

12.07.03.png)

DETALLES

Materiales en contacto con fluidos

Acero inoxidable 316L

Materiales sin contacto con fluidos

Acero inoxidable 304 | Acero inoxidable 304L

Sellos y temperatura soportada

Agua caliente

EPDM +95°C | HNBR +95°C | FKM +80°C

Vapor

EPDM +130°C | HNBR +121°C | FKM +121°C

Agua Fría

EPDM +1 a 2°C | HNBR +1 a 2°C | FKM +1 a 2°C

Tamaños

De 1” a 6” dependiendo el modelo

Presión de Operación

10 bar (145 psi)

Presión de aire para control

6 bar (87 psi) a 8 bar (116 psi)

Rugosidad partes sin contacto con el fluido

Ra ≤ 0.8 µm

Rugosidad partes sin contacto con el fluido

Ra 1.6 µm | Opcional superficies pulidas

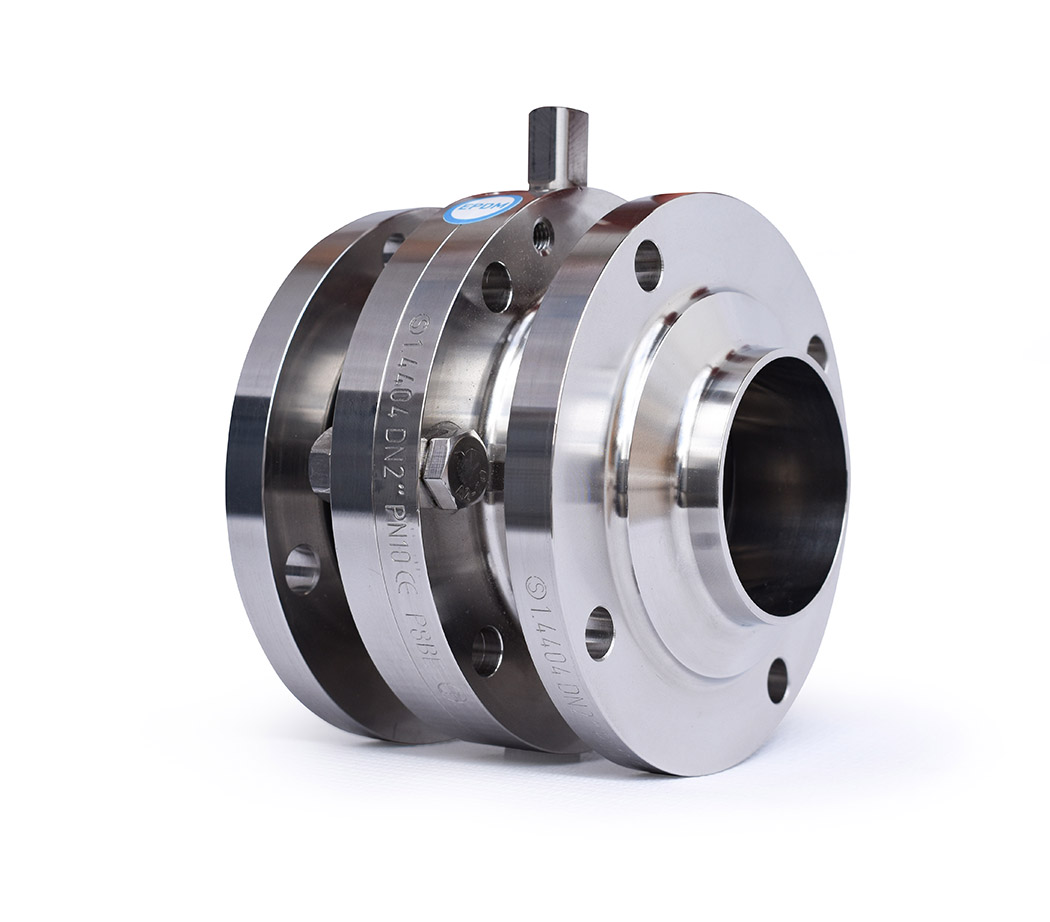

Válvulas tipo Mariposa y tipo Bola Higiénicas

Válvulas robustas con operación manual y/o Actuador neumático para utilizarse en proceso higiénicos.

DETALLES

Materiales en contacto con fluidos

Acero inoxidable 316L

Materiales sin contacto con fluidos

Acero inoxidable 304L

Sellos

EPDM | HNBR | VQM | FPM | PTFE Todos los sellos cumplen con FDA

Tamaños

10 bar (145 psi)

Presión de aire para control

6 bar (87 psi) a 8 bar (116 psi)

Rugosidad partes en contacto con el fluido

Ra ≤ 0.8 µm

Rugosidad partes sin contacto con el fluido

Ra ≤ 1.6 µm | Opcional superficies pulidas y electro pulidas

Conexiones a Proceso

Tri-Clamp | Mini Bridas | Conexión soldable | Coplees cónicos roscados

Operación

Palanca | Actuador neumático

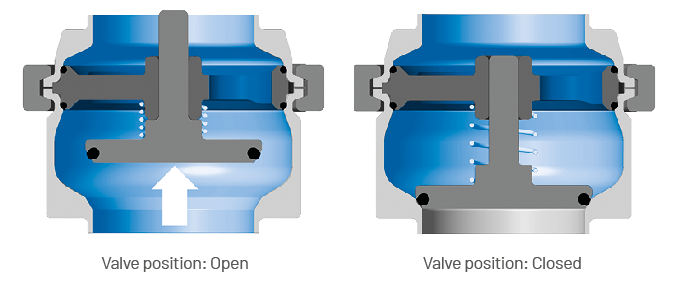

Válvula Check

Para evitar el retorno del flujo y están fabricadas en Acero inoxidable bajo estándares para industria alimenticia.

Abierta

Cerrada

DETALLES

Materiales

Acero inoxidable 316L

Tamaños

DN 10-150 / ½” a 6”

Presión de Operación

10 bar (145 psi)

Rugosidad

Ra ≤ 0.8 µm

Sellos

EPDM (FDA/EG1935) | FKM (FDA/EG1935)

Mirillas de flujo

Permiten no solo la posibilidad de ver el fluido, sino también instalar instrumentos, luces y válvulas de muestreo.

DETALLES

Diámetros

1” a 6”

Acabado Sanitario

Ra ≤ 0.8 µm

Rango de presión soportado vidrio

8 bar | 10 bar | 16 bar| 25 bar

Actuadores neumáticos

Se utilizan para accionar válvulas de mariposa, bola y obturador. Los actuadores neumáticos se usan comúnmente en todos los segmentos de aplicaciones higiénicas.

DETALLES

Tipos

Aire-Aire | Apertura por resorte | Cierre por resorte

Cabeza de control IntelliTop

Control, monitoreo e informes sobre todas las funciones de las válvulas de proceso de su planta.

DETALLES

Comunicación

24VDC | AS-Interface | DeviceNet | 110 VAC

Presión de aire para control

2.5 (36.25 psi) – 8.0 bar (116 psi)

Conexiones Neumáticos

0.6 mm | 0.8 mm | ¼” | 5/16”

Estatus Pantalla LED

Verde/amarillo/rojo/ configuración libre

Protección

IP65 | IP67 | IP69K

Aprobaciones

Ex II 3G Ex nA IIC T4 X Tamb +55°C

Ex II 3G Ex tD A22 T135°C X IP65/67

SensoTop

Unidad de retro-alimentacion de posición de la válvula.

DETALLES

Comunicación

24VDC | AS-Interface | DeviceNet | 110 VAC

Válvulas Solenoides

1 a 3 piezas | Rango de flujo de 200 l/min por válvula

Presión de aire para control

2.5 (36.25 psi) – 8.0 bar (116 psi)

Conexiones Neumáticos

0.6 mm | 0.8 mm | ¼” | 5/16”

Estatus Pantalla LED

Verde/amarillo/rojo/ configuración libre

Protección

IP65 | IP67 | IP69K

Aprobaciones

Ex II 3G Ex nA IIC T4 X Tamb +55°C

Ex II 3G Ex tD A22 T135°C X IP65/67

Válvulas de seguridad higiénicas.

Por sobrepresión

Válvula de seguridad con resorte, fabricada y verificada de acuerdo a las normas de equipos bajo presión.

DETALLES

Material

Acero inoxidable 316

Tamaños (metrico)

Modelos T12541 y T12542

25 | 32 | 40 | 50 | 65 | 80

Modelos T12545 y T12549

100 | 150 | 200

Temperatura de proceso

Modelos T12541 y T12542

Máximo 40°C ( 104°F)

Modelos T12545 | T12549 | T1254

Máximo 140°C ( 284°F)

Por vacío

Válvula de vacío para evitar implosión de tanque.

DETALLES

Material

Acero inoxidable 316

Tamaños (metrico)

25 | 32 | 40 | 50 | 65 | 80

100 | 150 | 200

Temperatura de proceso

Modelos T12541 y T12542

Máximo 40°C ( 104°F)

Modelos T12545 | T12549 | T1254

Máximo 140°C ( 284°F)

Conexión proceso

Rosca | Mini Bridas

Por alivio asiento simple

Alivia las áreas de presión en caso de acumulación excesiva de presión en espacios cerrados (tuberías, contenedores, taques). El medio de salida se puede descargar o devolver/dirigir a un sistema cerrado.

DETALLES

Material

Acero inoxidable 316

Tamaños

DN 25 a DN 100 / 1” a 4

Presión de ajuste

0.5/1.0 a 10.0 bar (7/15 a 145 p)

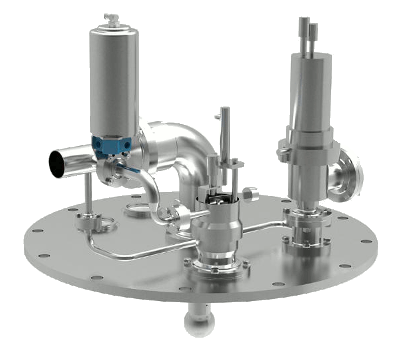

Sistema TankTop para protección y autolimpieza de tanques

Ofrece un sistema compacto para tanques simple y confiable que permite agregar y/o eliminar gases y líquido de limpieza CIP mediante una sola conexión a proceso.

Autolimpieza de tanques, Sprayball

13.19.49-imac.png)

1. El "sprayball" limpia el tanque

2. El asiento móvil está precargado por muelles. La limpieza cierra el asiento automáticamente sin activación externa. El líquido de limpieza ingresa al tubo de rociado y "sprayball".

3. Los orificios perforados en la curva permiten limpiar la válvula de seguridad, así como el área del asiento.

Ventilación de aire

13.19.59-imac.png)

1. Valvula de seguridad con muelles.

2. Valvula de vacio con contra peso.

3. El asiento elevable está precargado por muelles para permitir que el tanque respire. El intercambio de gases para carga de presión, vaciado y llenado está asegurado.