La puerta hacia la industria 4.0

En la actualidad existen algunas plantas industriales con sistemas de control obsoletos, algunos de estos sin más soporte del fabricante, esta situación incrementa los costos de mantenimiento asi como el riesgo de continuidad del proceso. Por otra parte no se obtienen los beneficios de la tecnología actual de la industria conectada.

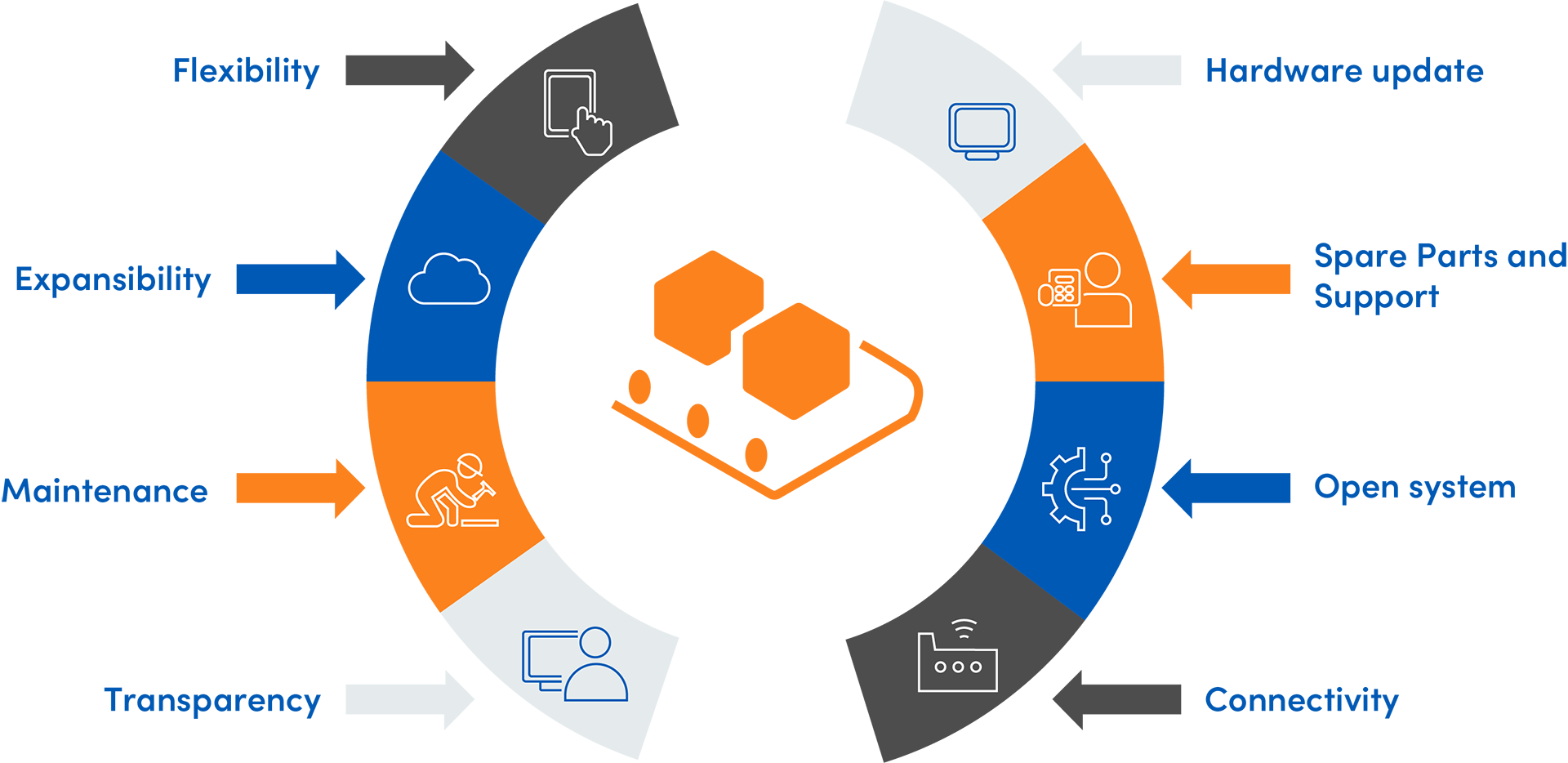

Beneficios de migrar sus sistemas de control con ECN Automation:

Flexibilidad:

Arquitectura abierta e integrada para incrementar su capacidad.

Conectividad:

Redes de comunicación que interconectan todos los elementos del sistema y que dan acceso a valiosa información para generar reportes e indicadores que beneficien la eficiencia del proceso.

Confiabilidad:

Sistemas de control e información con tecnología actual que asegura una operación continua con mínimo mantenimiento.

ECN Automation ha desarrollado desde 2005 un área de enfoque a migraciones de sistemas de control ya sea DCSs o PLCs acumulado más de 300 proyectos exitosos de los cuales más de 20 son sistemas propietarios DCS.

Basados en nuestro expertise y conocimiento técnico desarrollamos la metodología DCSTEP que reduce al mínimo riesgos de conversión, tiempos de paro y resistencia al cambio derivado de la implementación de nueva tecnología.

El objetivo de DCSTEP es actualizar tecnología con agilidad, erradicando los riesgos asociados a la obsolescencia sin que signifique un proceso doloroso de reaprendizaje y una implementación llena de riesgos de paro e incertidumbre de operación.

Migración la ventana a la industria 4.0 es nuestro lema ya que la actualización tecnológica, en un proceso terso, da acceso a nuevas eficiencias escaladas al subirse a la tendencia tecnológica de la digitalización.

DCS (Bailey, Honeywell, Foxboro, Delta V)

ECN Automation con su gran experiencia en migraciones de DCS obsoletos, realizando las mejores practicas para mitigar los riesgos y la implementación mas eficientes utilizando DCS como Plant PAX para lograr un sistema de la mas alta tecnología, orientado hacia la industria 4.0.

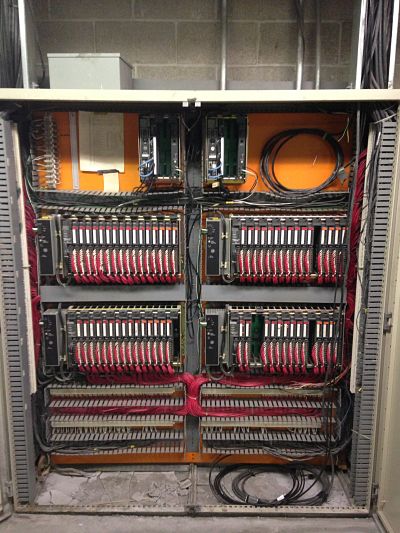

PLC (PLC5, SLC500, Siemens, GE)

Con la gran experiencia que ECN Automation tiene en actualización, conversión o Migración de PLC´s obsoletos, les ayuda a mantener a nuestros clientes, PLC’s de ultima tecnología en sus sistemas de control, lo que incrementa y optimiza los procesos de sus plantas.

La metodología de como realizar un proyecto de migración o conversión juega un rol importantísimo, por que como bien sabemos detener un proceso para cambiar todo el sistema de control muchas veces no es posible, debido a industrias donde la operación nunca se detiene. Es por ello que esta metodología nos puede apoyar mucho a ser eficientes en estos proyectos.

Metodología de 3 fases

ECN Automation basado en nuestra experiencia y conocimiento en la Migración de Sistemas de Control ha desarrollado una metodología basada en 3 fases que aseguran una transición suave a la modernidad.

Beneficios

Antes

Después

Casos de Éxito

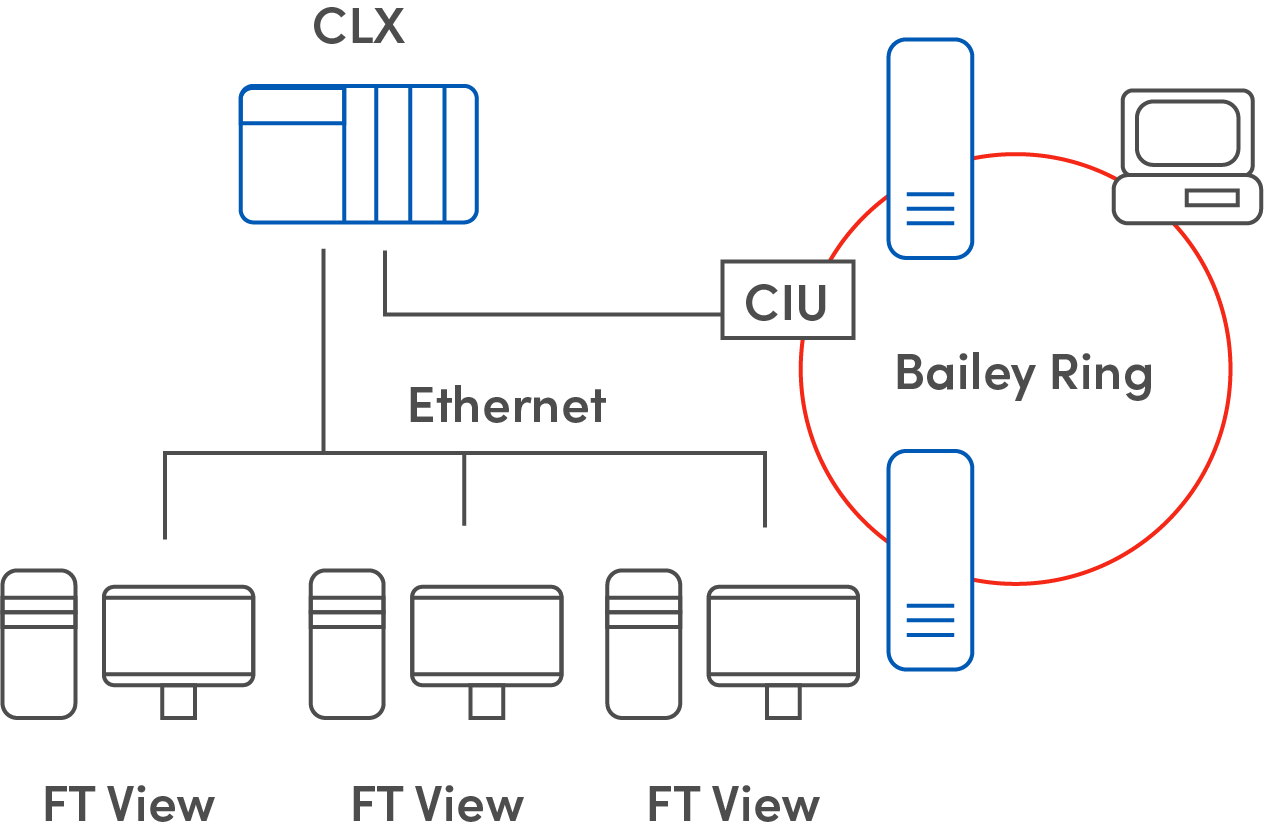

01

Cliente:

Empresa Minera, extracción de hierro.

Alcance:

Migración de un Sistema DCS de Bailey a ControlLogix.

.png)

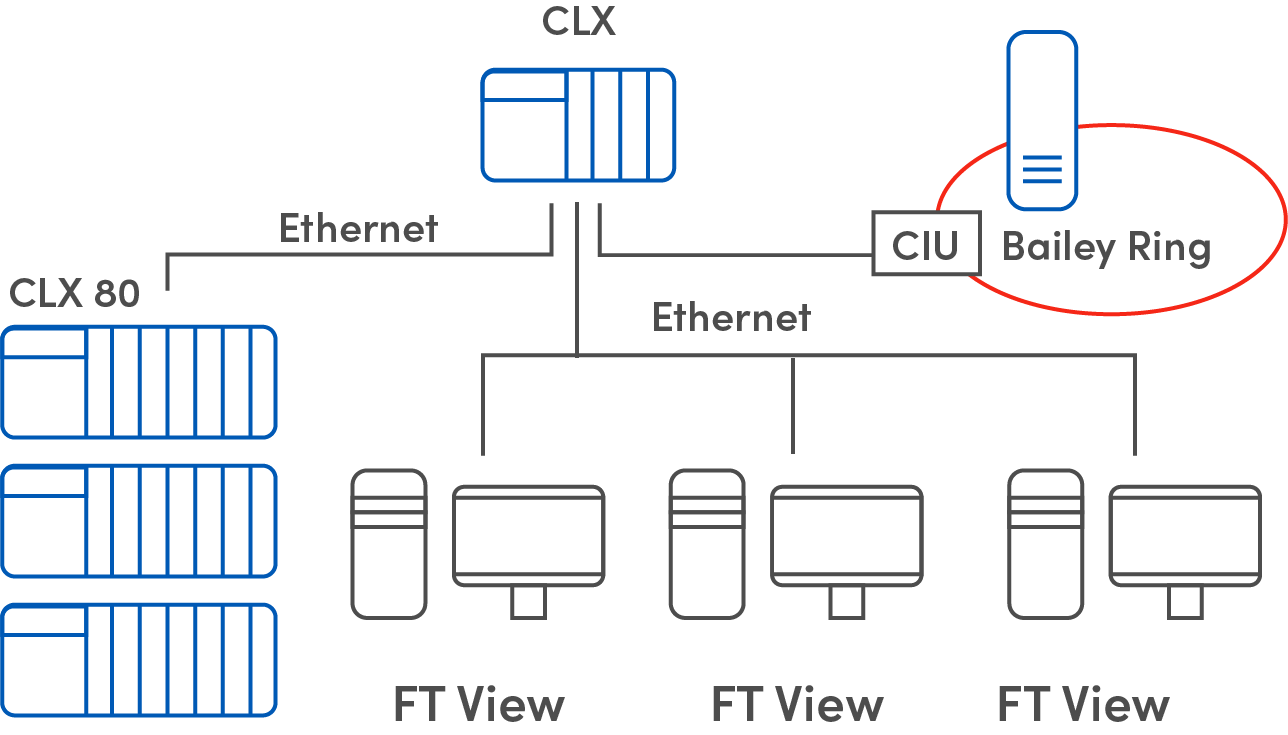

02

Cliente:

Empresa Minera, extracción de cobre.

Alcance:

Actualización de máquina deshojadora de placas de cobre.

.png)

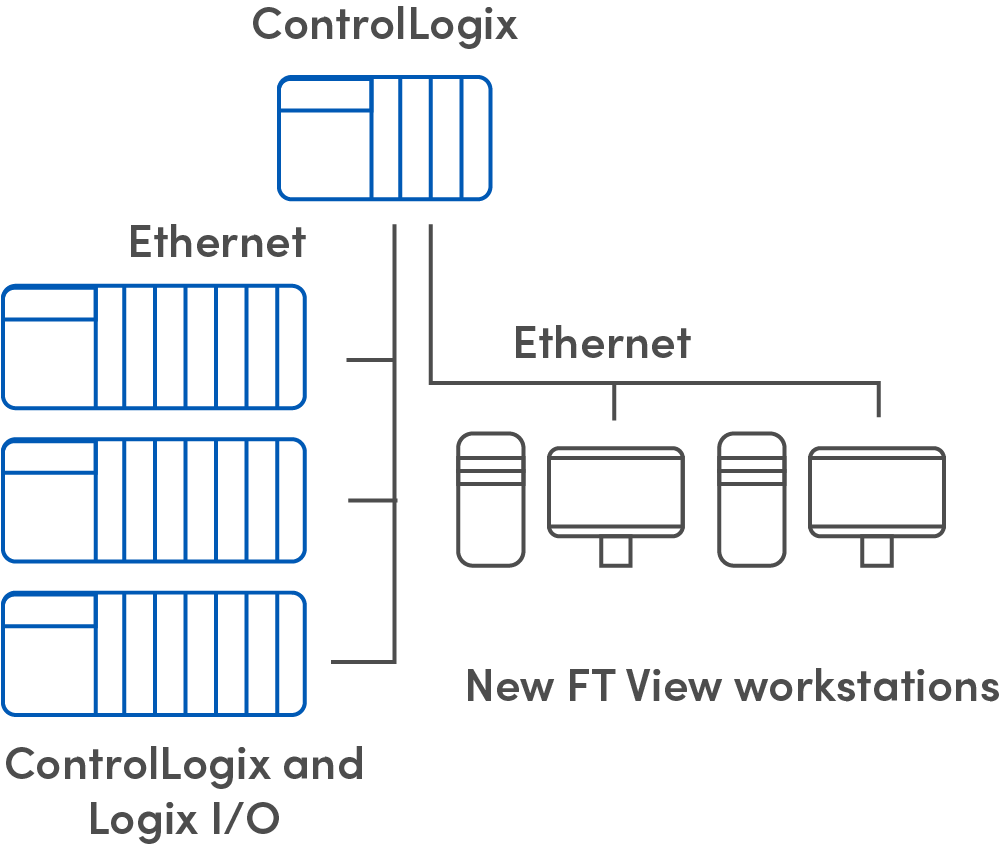

03

Cliente:

Empresa Minera, extracción de Wollastonita.

Alcance:

Migración de Sistema DCS Bailey a ControlLogix para área WET.

.png)