PRODUCTS OPTIMIZACION METALURGICA

PRODUCTS OPTIMIZACION METALURGICA

Gemelo digital de molienda SAG

El Gemelo Digital de Molienda SAG consiste en una plataforma digital que agrupa diferentes herramientas de predicción, simulación y análisis operacional que generan una replica virtual del molino y es utilizada para diagnosticar la condición presente y asistir estrategias de control en favor de la estabilidad operacional y maximización de tratamiento.

¿Que información entrega?:

Módulos del sistema

Componentes de software de la plataforma

Analítica de variable operativa del molino.

Con este aplicativo se genera el caso de negocio inicial del proyecto y nos permite mostrar gráficas avanzadas para mostrar la estadística descriptiva del proceso.

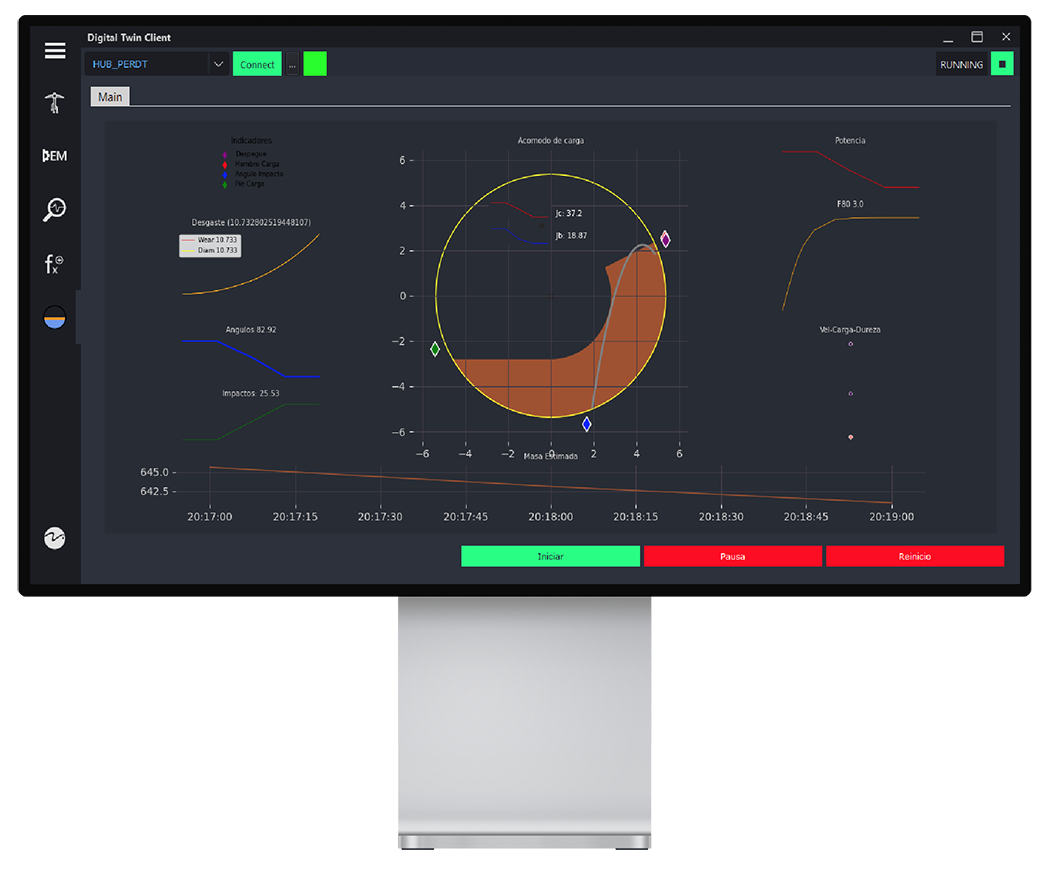

Estimador del estado del molino.

Este aplicativo estima el nivel de carga total (Jc) y nivel de bola (Jb) y esta basado en un algoritmo de optimización con restricciones y un modelo de predicción de potencia del Molino SAG.

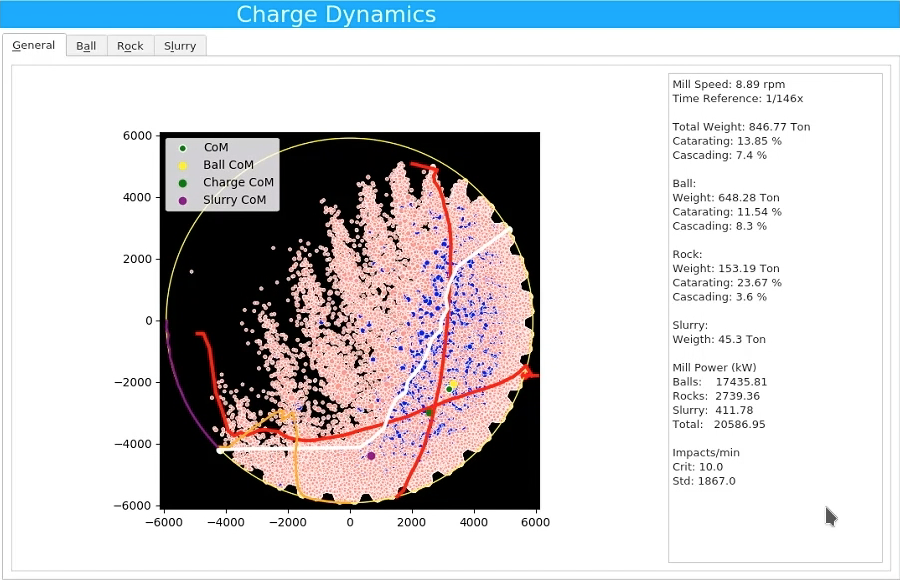

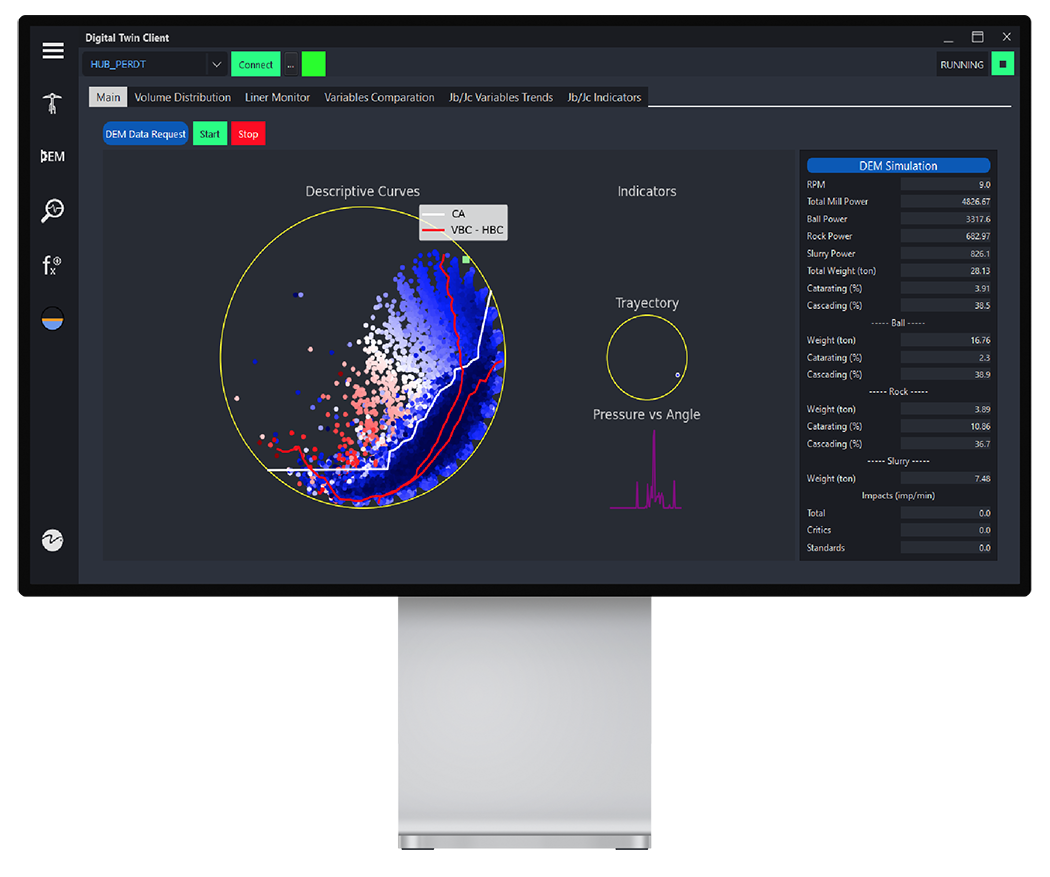

Simulador DEM (Discrete Element Method).

Este aplicativo simula la física del molino y se utiliza para mantener calibrados los parámetros del estimador de estado del molino, en base a la condición actual de desgaste de los revestimietos del molino.

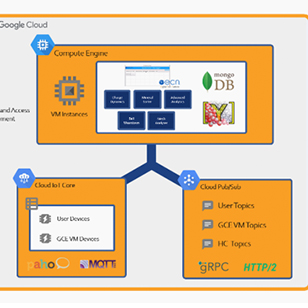

Integrador de datos en la nube.

Este aplicativo nos permite el envío en tiempo real de las variables de proceso del molino y obtener de regre-so los resultados que entre-ga el gemelo digital alojado en la nube al cliente de visualización local instalado en la planta minera.

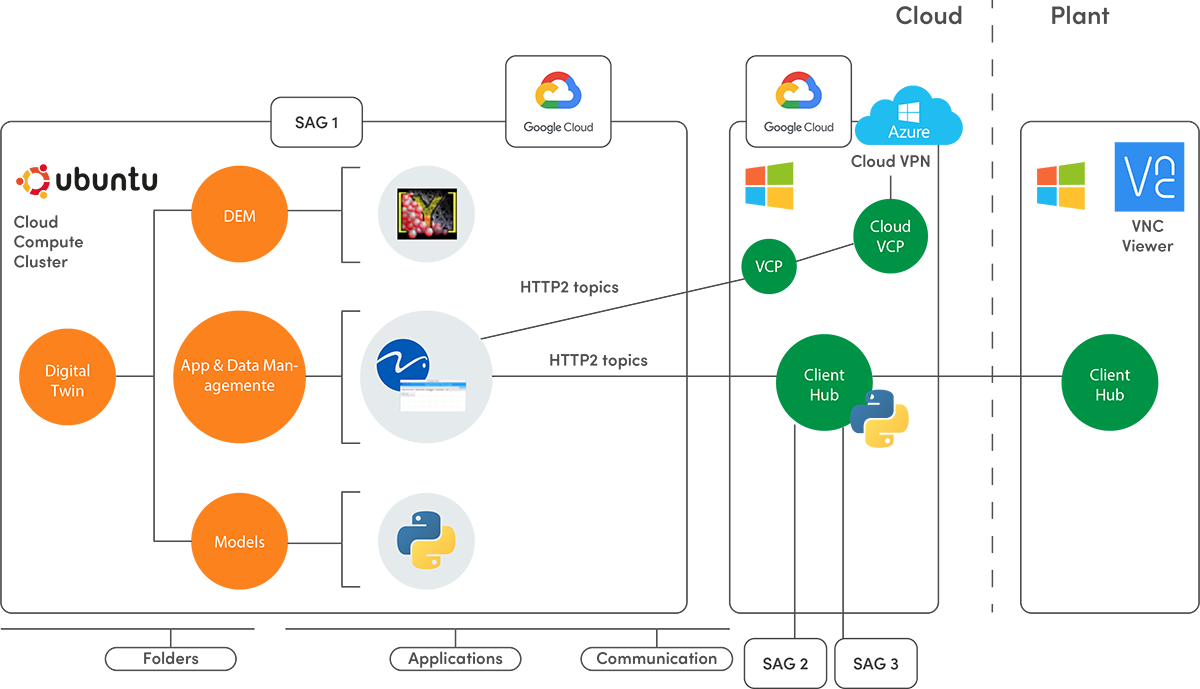

Arquitectura del Gemelo Digital en la nube:

El Gemelo Digital esta alojado en la nube de Google, llamada Google Cloud Platform (GCP). Los datos de planta se integran utilizando el IoT Core de GCP, en donde mediante una conexión segura, las variables de proceso del circuito de molienda son enviados mediante estas tres opciones:

Ventajas

Desventajas

Arquitectura en la nube:

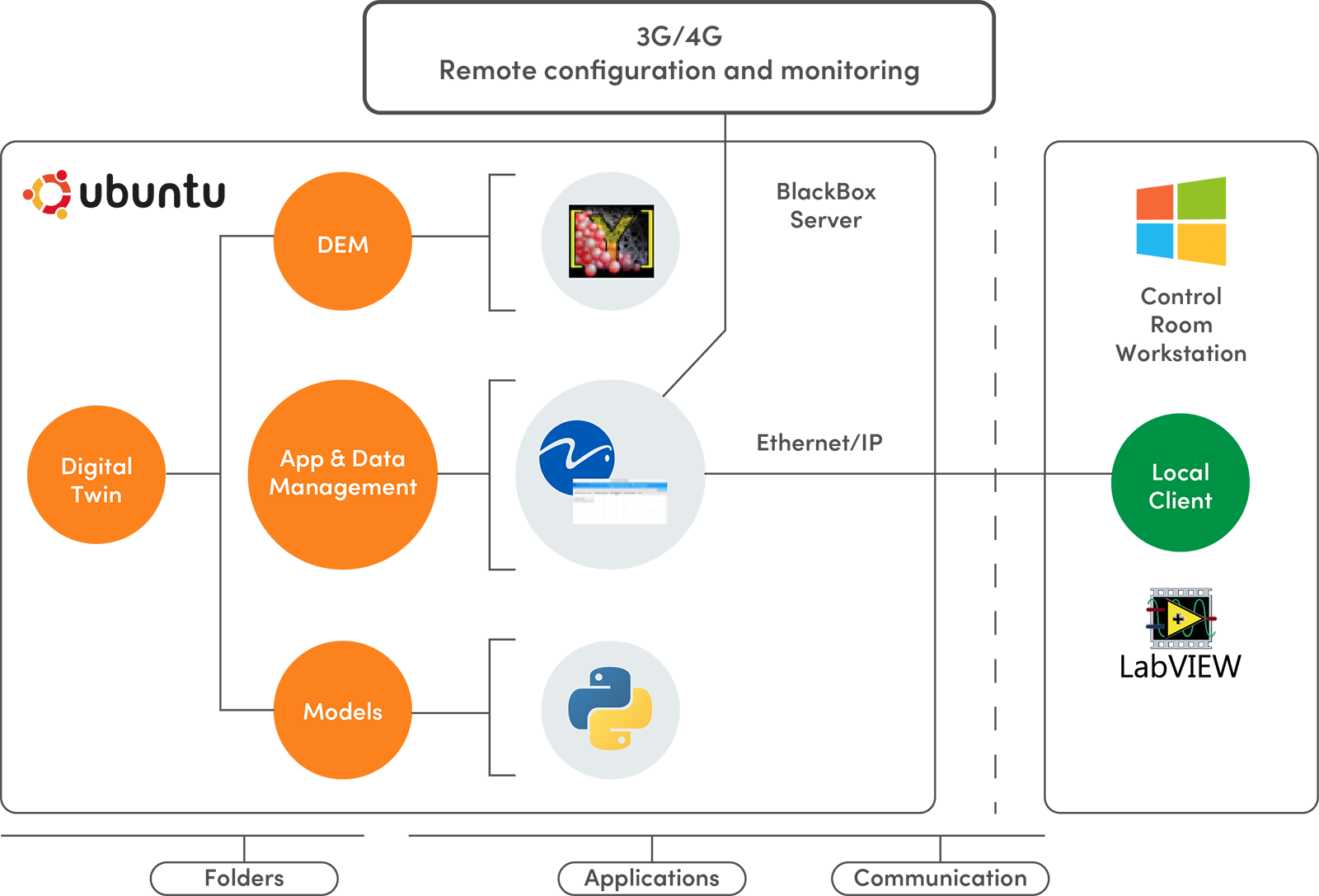

Arquitectura con servidores locales (On-Premise)

El Gemelo Digital "On-Premise", se instala en servidores locales bajo el concepto de "Caja Negra", la cual solo tiene conectividad al exterior mediante un puerto de red industrial para conectarse al cliente local desarrollado en Labview y cuanta con una conectividad vía 3G o 4G para conectarlo a Internet para su configuración y mantenimiento remoto.

Ventajas

Desventajas

Beneficios del Sistema