INDUSTRIAS CUIDADO DE LA SALUD

INDUSTRIAS CUIDADO DE LA SALUD

Eficiencia en proceso CIP/SIP (Cleaning/Sterilization in place)

Los procesos de limpieza y/o esterilización en sitio (CIP o SIP) son prioritarios en la producción de alimentos como productos de la salud. La operación eficiente de estos sistemas asegura el cumplimiento de normativas de limpieza y del tiempo de utilización de la maquinaria y procesos de producción.

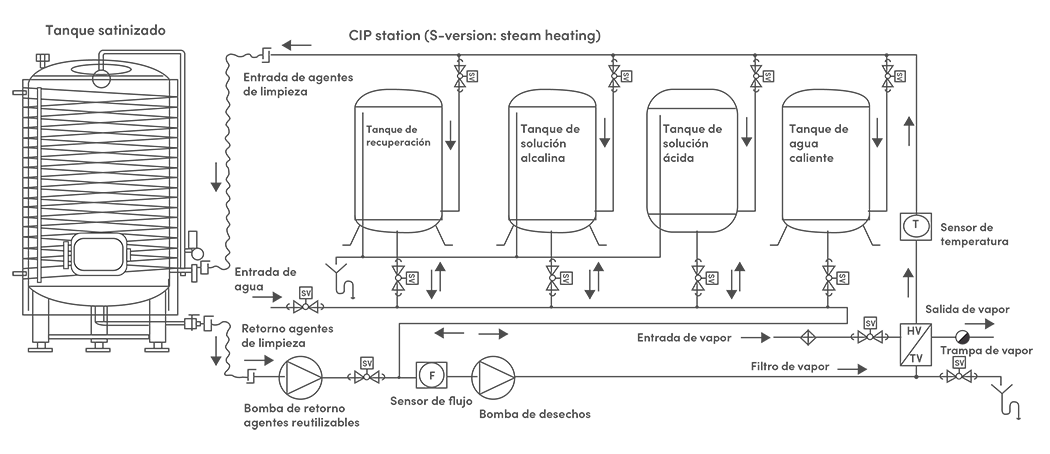

Diagrama de tubería e instrumentación (DTI) de un proceso CIP

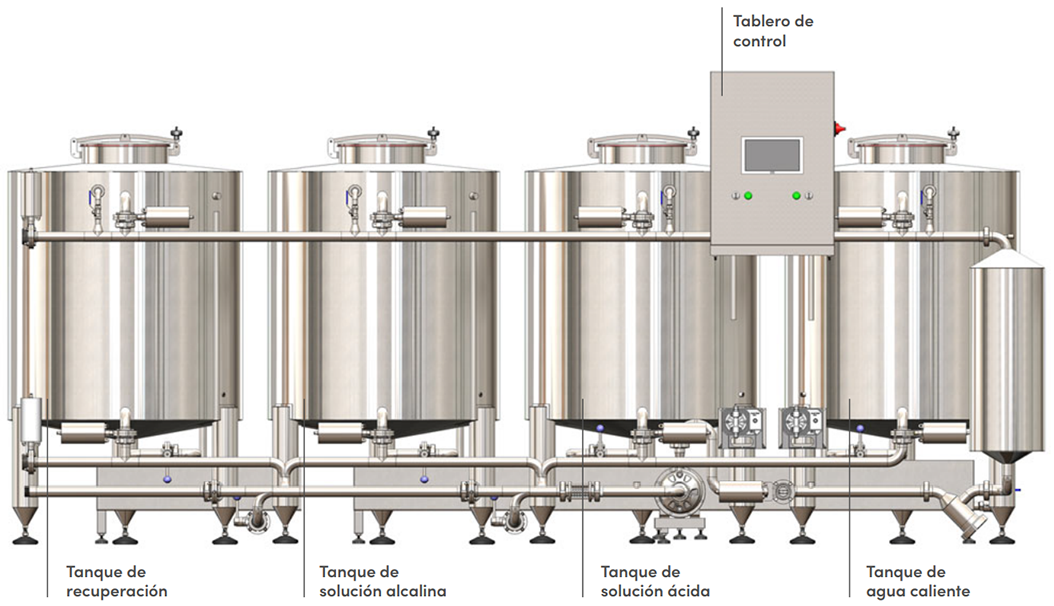

Sistema automatizado CIP & SIP

La automatización de la operación en un sistema CIP garantiza el estricto cumplimiento de los estándares de limpieza obteniendo ahorros en consumo de energía y de productos químicos así mismo se optimiza el tiempo de duración de este proceso permitiendo incrementar la disponibilidad de maquinaria de producción. Beneficios de la automatización del proceso CIP:

Pantalla de proceso HMI

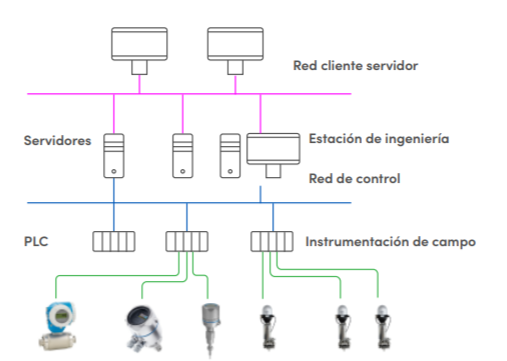

Arquitectura de control CIP

Descripción del proceso CIP:

Primera fase:

Se realiza un empuje con agua limpia para dejar sin producto la línea que se va a limpiar.

Segunda fase:

Se realiza un enjuague con agua recuperada, esta agua es una solución de agua + sosa obtenida del enjuague posterior a la fase de recirculación con sosa; con el beneficio que nos permite realizar una primera pasada por el circuito con una solución con un poder de limpieza superior que el agua y nos permite ahorrar agua y sosa.

Tercera fase:

Se realiza una recirculación de agua con sosa con una concentración del 2-4% durante el tiempo establecido

Cuarta fase:

Se realiza un enjuague con agua de red, que recuperaremos en el depósito de agua recuperada y que nos servirá para realizar el primer enjuague de la próxima limpieza.

Quinta fase:

Solo en caso de la utilización de vapor (SIP) o algún agente para esterilización.

Sistema CIP automático

Elementos de medición y control

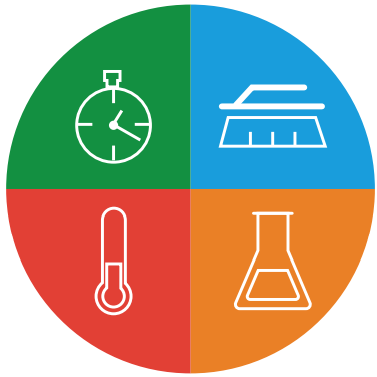

Para garantizar una limpieza completa deben tenerse en cuenta cuatro factores que se combinan entre sí: la acción mecánica, la química, la temperatura y el tiempo. Estos cuatro elementos son los que conforman el llamado círculo de Sinner y que pueden ser monitoreados a través de la instrumentación y control.

El circulo de Sinner de la limpieza

Producto químico

Limpieza química

Transmisor de conductividad para medición de concentración de detergente.

Energía mecánica

Medición de caudal

Medición del caudal para asegurar una velocidad mínima y la recirculación de agente limpiador

Temperatura

Medición de temperatura

Medición de temperatura para una reacción eficiente de los agentes de limpieza.

Tiempo

Válvula automática

Válvula higiénica de mariposa automática para el corte entre fases