INDUSTRIAS CUIDADO DE LA SALUD PROCESOS

INDUSTRIAS CUIDADO DE LA SALUD PROCESOS

Manufactura y dispositivos médicos.

El crecimiento de la población, el aumento del gasto en salud, la incidencia de enfermedades crónicas, el desarrollo de la industria manufacturera y la adquisición de nuevas tecnologías son factores que contribuyen a un dinamismo cada vez mayor en la producción de dispositivos médicos. Por eficiencia y ahorros energéticos en la manufactura y producción de estos, son importantes.

Manufacturing Execution System MES

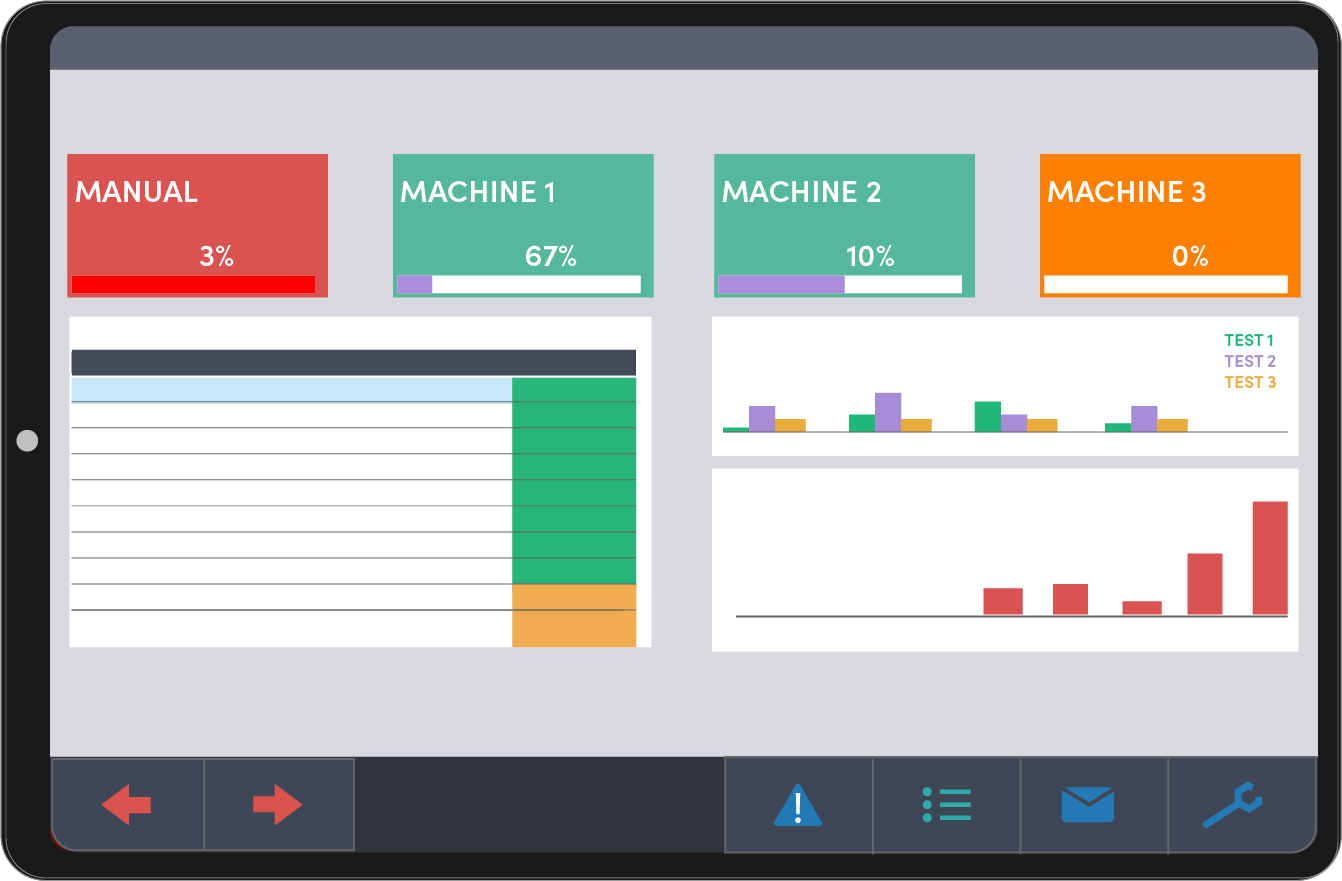

Sistema MES que le permitirá el control y la gestión global de la información de todas sus plantas de producción y la perfecta integración de los datos con su ERP. Integra los diferentes módulos de la solución en un entorno fácil de utilizar y rápido de implementar donde se puede desplegar información valiosa para tomar decisiones oportunas.

Módulos

Control de producción

Calidad y trazabilidad

SCADA

Dashboards

Planificación de O.F.

Gestión Trenes Laminación

Producción

Calidad

Mantenimiento

Trazabilidad

Soluciones MES

Producción OEE

Control y la gestión global de sus fábricas, totalmente integrado con su ERP, la solución utiliza la captura automática de datos de cualquier máquina o sensor para obtener datos objetivos, fiables y en tiempo real.

Eficiencia energética

En sistema simple de registro de parámetros o variables que varían en el tiempo. El sistema se comunica con cualquier dispositivo industrial que tenga una salida de comunicaciones o una salida en tensión o corriente.

Mantenimiento predictivo

Valúa el estado de la maquinaria y recomienda intervenir o no en función de su estado, lo cual produce grandes ahorros.

Trazabilidad

Permite la gestión de los lotes de fabricación, de materias primas, semielaborado y producto final.

MAPEX BI

Mapex BI centraliza la información para una estructura sencilla, crear pantallas y reportes dinámicos en base a las necesidades del cliente.

Calidad

Sistema de gestión de calidad que le permitirá tener un control fiable y rápido de toda la información en su departamento

Características

Beneficios

Compatible en cualquier tipo de dispositivo

Monitores

Tablet

Smartphone

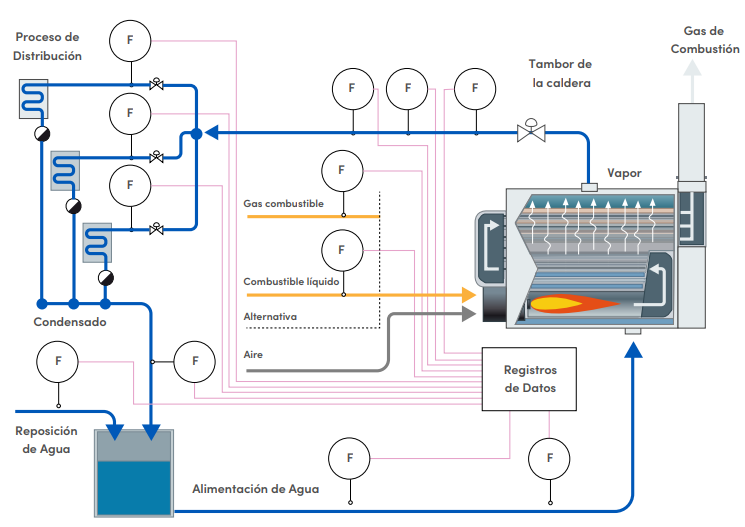

Eficiencia en calderas

Ya sea para determinar el rendimiento actual de sus equipos de caldera existente, optimizar la operación de planta o evaluar los consumos de gas de combustión, puede confiar en nuestra experiencia y conocimiento de la industria. Mejora del control de calderas y de la seguridad de planta mediante las soluciones de medición y monitorización avanzada. Eficiencia a través del cumplimiento y del coste por unidad de consumo.

Ventajas del sistema:

Vapor

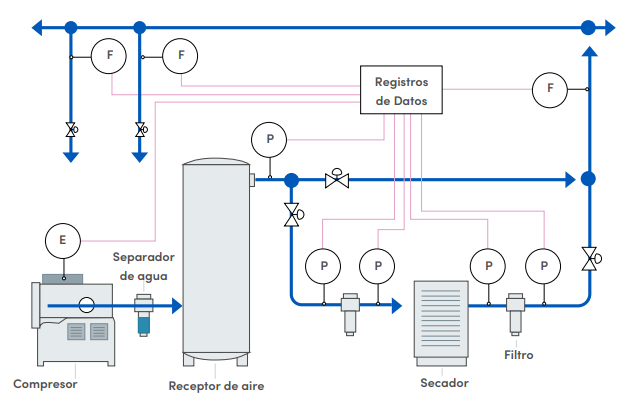

La eficiencia del compresor

El uso de indicadores KPI significativos, mantienen informados a los operarios, así como a gerencia. Esta la gestión energética puede hacerse constructivamente. Dado que hasta el 85% de los costes totales de un sistema de aire comprimido principalmente lo constituyen los costos energéticos.

Para determinar la eficiencia tenemos que:

Utilizando caudalímetros en distintos puntos en el sistema, implementado esta solución podemos:

Soluciones energéticas - aplicaciones de aire comprimido