PRODUCTOS ELEMENTOS DE MEDICIÓN Y CONTROL EQUIPO DE PROCESO

PRODUCTOS ELEMENTOS DE MEDICIÓN Y CONTROL EQUIPO DE PROCESO

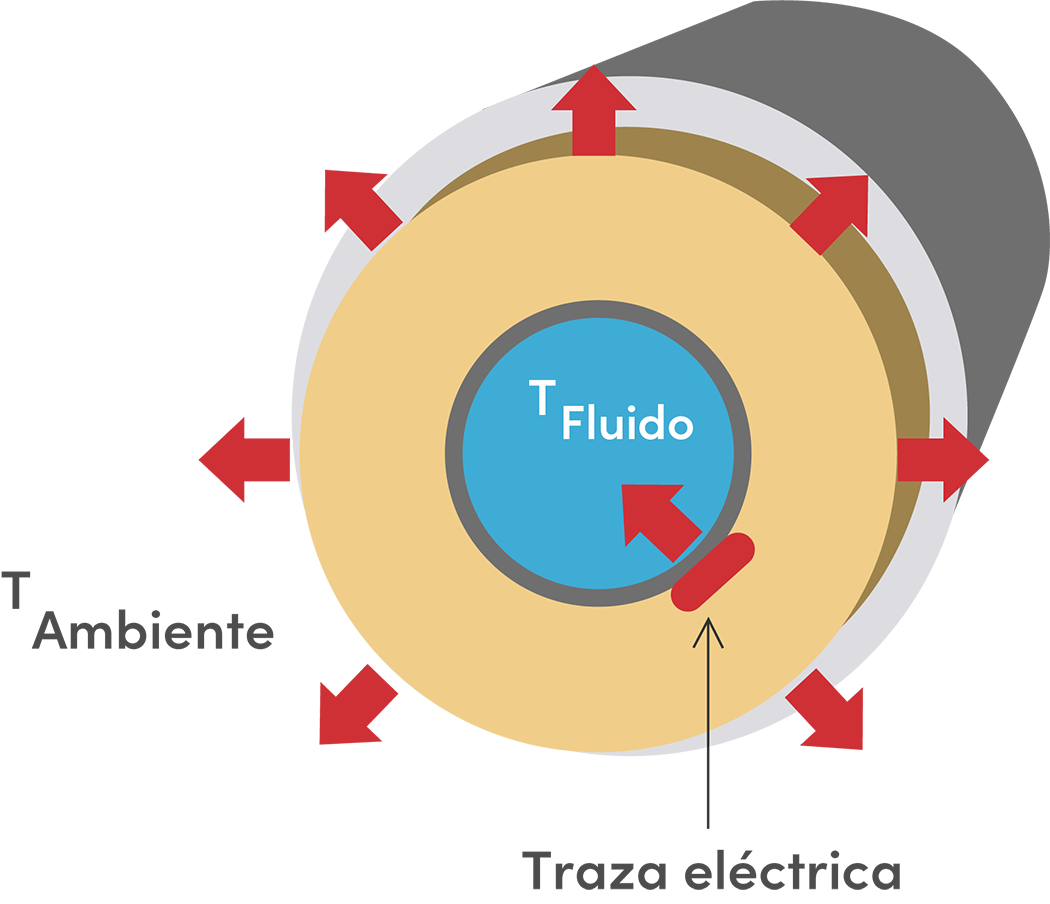

El trazado eléctrico le permitirá conservar una temperatura deseada a lo largo de todo su sistema de tuberías por donde conduce ese fluido, evitando taponamiento por cristalización o incremento de viscosidad que incremente la energía de bombeo.

.png)

Traza autoregulable

Cables calefactores eléctricos mantienen la temperatura de los fluidos, son el apoyo ideal para compensar la pérdida de calor a través del aislamiento térmico en tuberías, recipientes y equipos asociados.

Aplicaciones

Mantiene la temperatura del fluido, ejemplos de aplicación

• Líneas de químicos

• Ductos petroleros

• Azufre

• Grasas

• Alimentos

• Químicos

• Aceites

• Parafinas

• Líneas de sistemas contra incendios

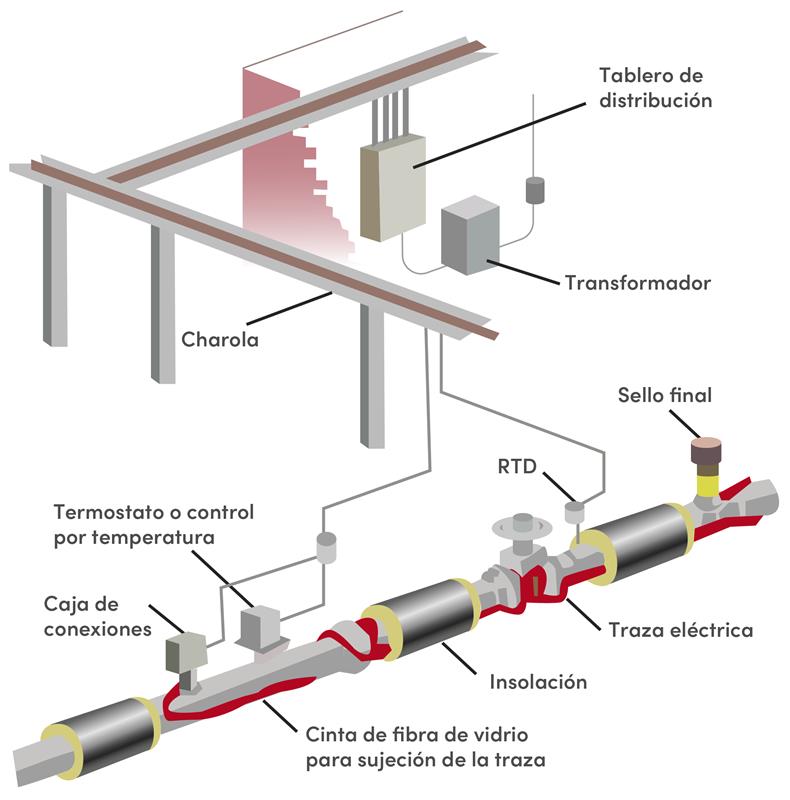

Componentes del sistema de traza eléctrica.

Tipos de traza

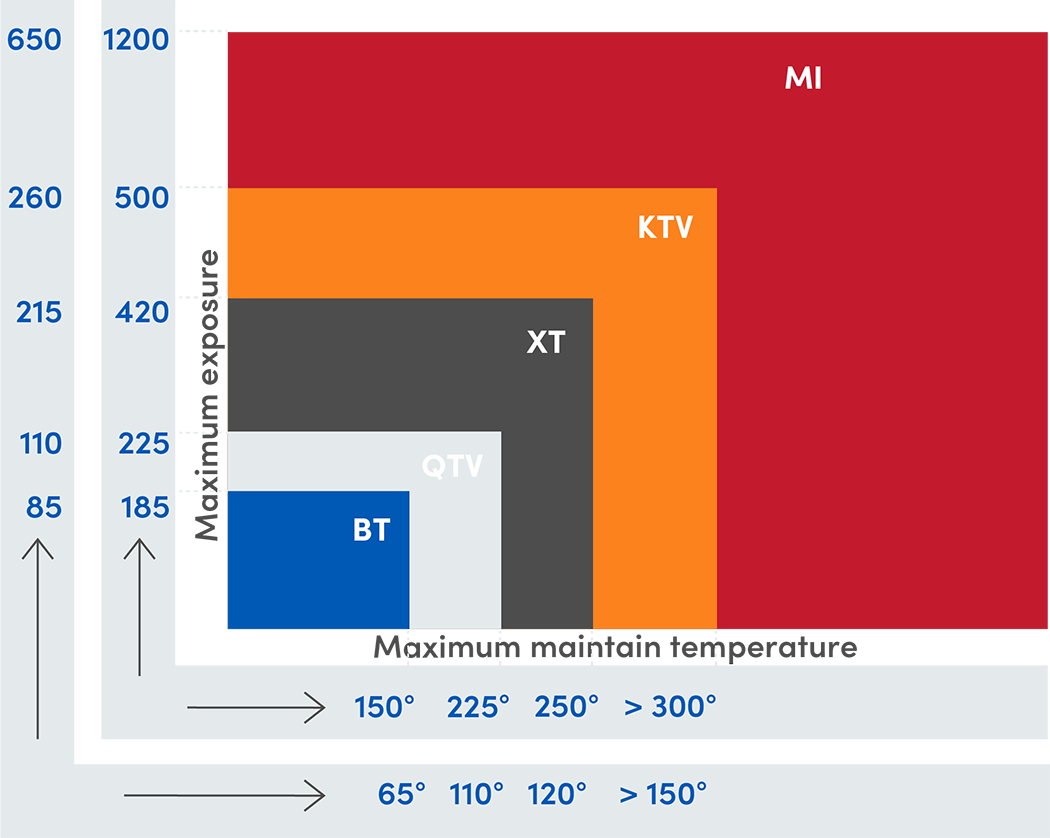

Cable BTV

Temperatura máxima a mantener 150°F (65°C)

Temperatura máxima de exposición 185°F (85°C)

Consumo energético a 50°F: 3, 5, 8, 10 W/ft

Protección contra congelamiento del fluido y mantenimiento de la temperatura de proceso.

Usado para:

Regaderas de emergencia

Líneas de sistemas contra incendios

Agua de proceso

Producción de chocolate

Líneas de sosa cáustica

Cable QTVR

Temperatura máxima a mantener 225°F (110°C)

Temperatura máxima de exposición 225°F (110°C)

Consumo energético a 50°F: 10, 15, 20 W/ft

Protección contra congelamiento del fluido y mantenimiento de la temperatura de proceso. Un consumo energético mayor que el BTV.

Usado para:

Hidrocarburos

Ácidos

Fertilizantes

Cable XTV

Temperatura máxima a mantener 250°F (121°C)

Temperatura máxima de exposición 482°F (250°C)

Consumo energético a 50°F: 5, 10, 15, 20 W/ft

Protección contra congelamiento del fluido y mantenimiento de la temperatura de proceso líneas de vapor limpio.

DETALLES

Aceites

Polímeros

Combustibles pesados

Cable KTV

Temperatura Máxima a mantener 300°F (150°C)

Temperatura Máxima de exposición 482°F (250°C)

Consumo energético a 50°F: 5, 8, 15, 20 W/ft

Protección contra congelamiento del fluido y mantenimiento de la temperatura de proceso líneas de vapor limpio.

Usado para:

Aceites

Polímeros

Combustibles pesados