PRODUCTOS SOLUCIÓN DE INDUSTRIA 4.0

PRODUCTOS SOLUCIÓN DE INDUSTRIA 4.0

Realidad aumentada

Nuestra solución combina información para usuarios móviles a través de una interfaz que superpone datos en tiempo real y objetos virtuales en máquinas, gabinetes de control o procesos; lo que permite a los usuarios tener acceso inmediato a la información relevante de la máquina y el proceso.

Esta tecnología puede ser aplicada para visualización de datos de proceso en tiempo real, visualizar hojas técnicas/planos, videos, así como procedimientos para llevar a cabo alguna tarea específica. Gracias a esta tecnología es posible digitalizar y centralizar toda la documentación de su proceso para poder consultarla en el cualquier momento.

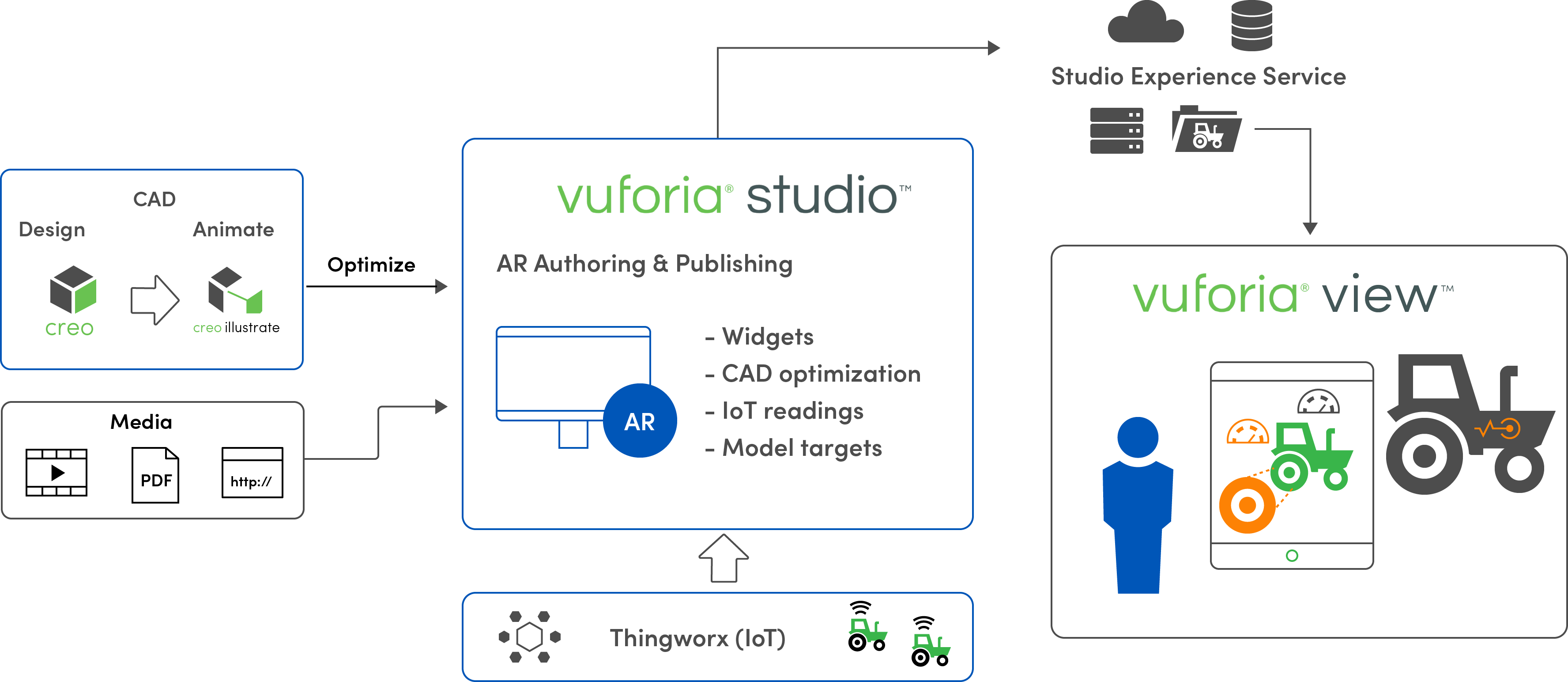

Arquitectura de la solución

Esta solución permite conectar la información de los sistemas de control existentes en planta en una estación central donde se ejecuta la aplicación de realidad aumentada, una conexión WIFI habilita los contenidos para que puedan ser mostrados en los dispositivos móviles como tablets y celulares.

Create & scale industrial AR

Beneficios

Metodología

Paso 1

Se colecta toda la información relevante a los activos / proceso a monitorear, ya sean guías de mantenimiento, variables de proceso, documentación; en el caso de aplicaciones de realidad mixta se hace un escaneo de la máquina o proceso para la cual se mostrará información.

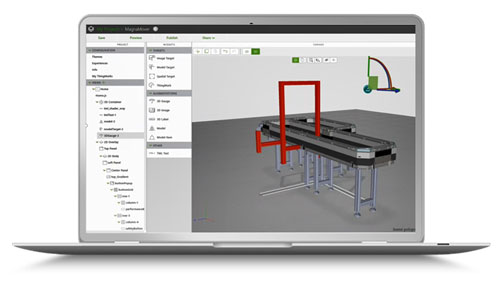

Paso 2

Utilizando la herramienta web de diseño de aplicaciones se construye la experiencia de realidad aumentada que pueden incluir datos en tiempo real, documentos, videos, instrucciones paso a paso para realizar una actividad.

Paso 3

Visualización de la experiencia a través de app disponible para sistemas Android e iOS. Las experiencias pueden mostrarse mediante el escaneo de una marca o bien mostrando la experiencia sobre un área o superficie.

Ejemplos de uso

Frente a una máquina o una línea de producción.

Acceso inmediato, en tiempo real, a información relevante en el campo para operaciones y mantenimiento; historial de la máquina, variables de proceso, documentos (instalaciones, instrucciones, electricidad diagramas, etc.)

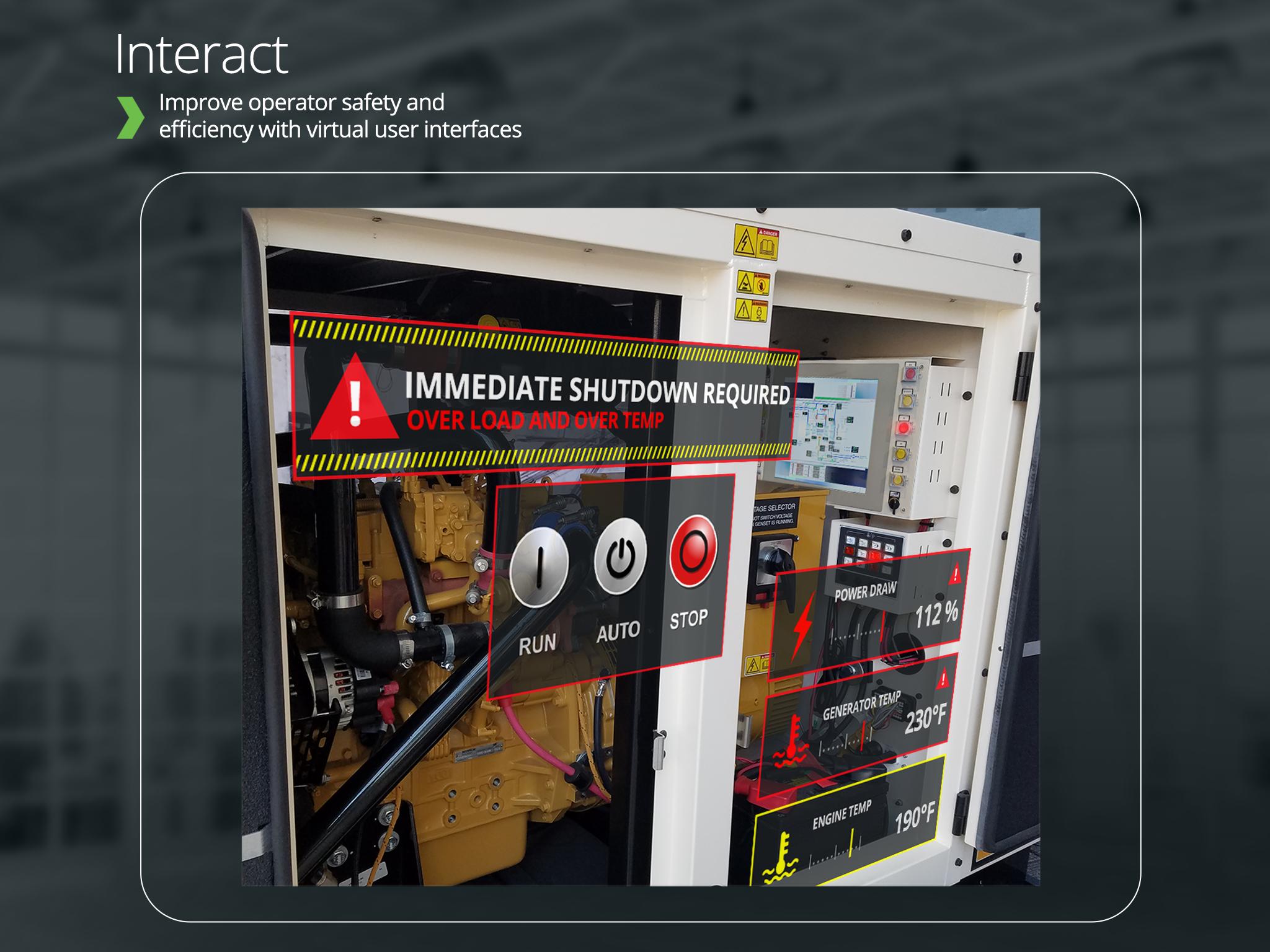

Frente a un tablero o una parte oculta de una máquina.

Diagnóstico rápido sin necesidad de abrir físicamente el gabinete gracias a las puertas virtuales mostradas en realidad aumentada que abren el gabinete, con la capacidad de visualizar información de estatus, valores de variables (potencia, velocidad, etc.) documentos (instalaciones, manuales, diagramas eléctricos, etc.).

Para una vista general

Vista simultanea de la realidad y los datos, detección rápida y segura de anomalías (visualización de alarma, variables de proceso significativas) y acceso a KPI (parámetros de visualización e información clave, progreso de producción, indicadores de rendimiento, etc.).