Monitoreo y análisis de tamaño de partícula.

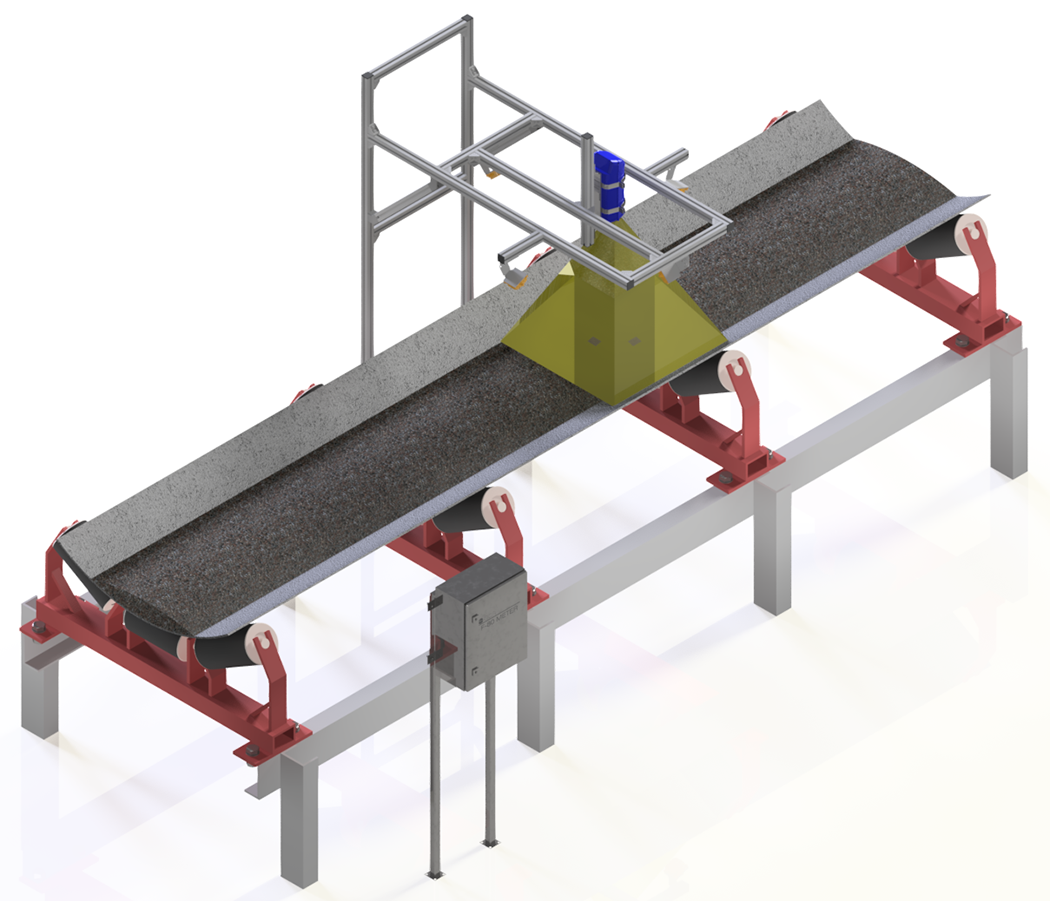

Es un sistema basado en visión artificial que mide la distribución del tamaño de partículas en bandas transportadoras y es aplicable a los circuitos de trituración y molienda.

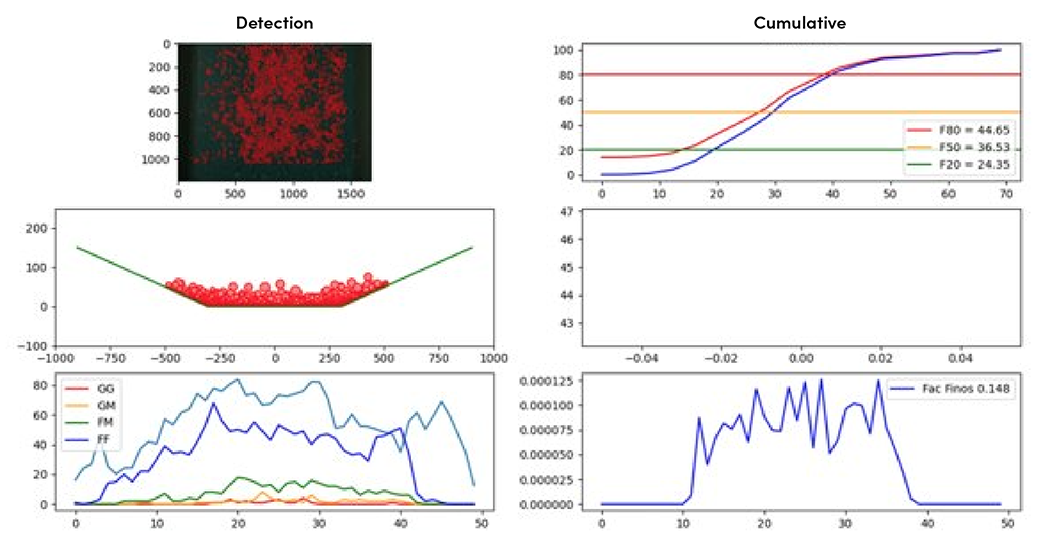

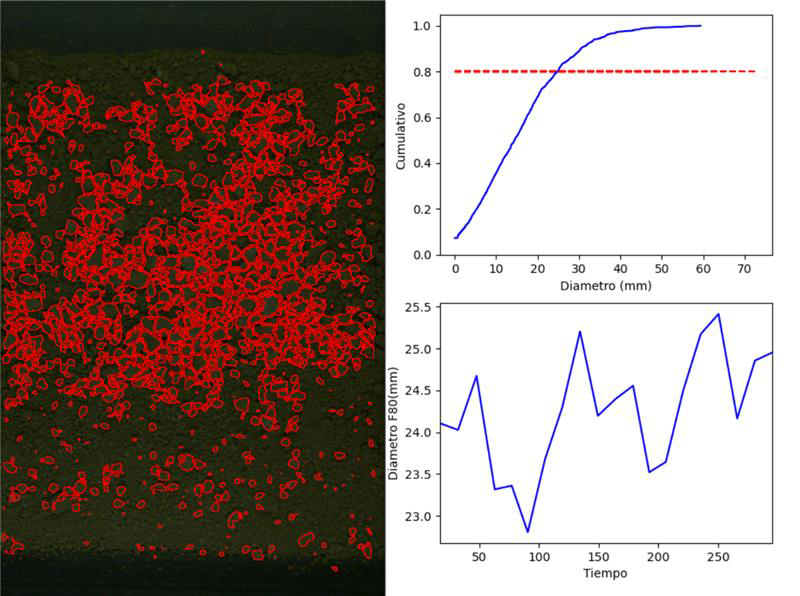

Qué información entrega:

Módulos del sistema

Componentes del sistema

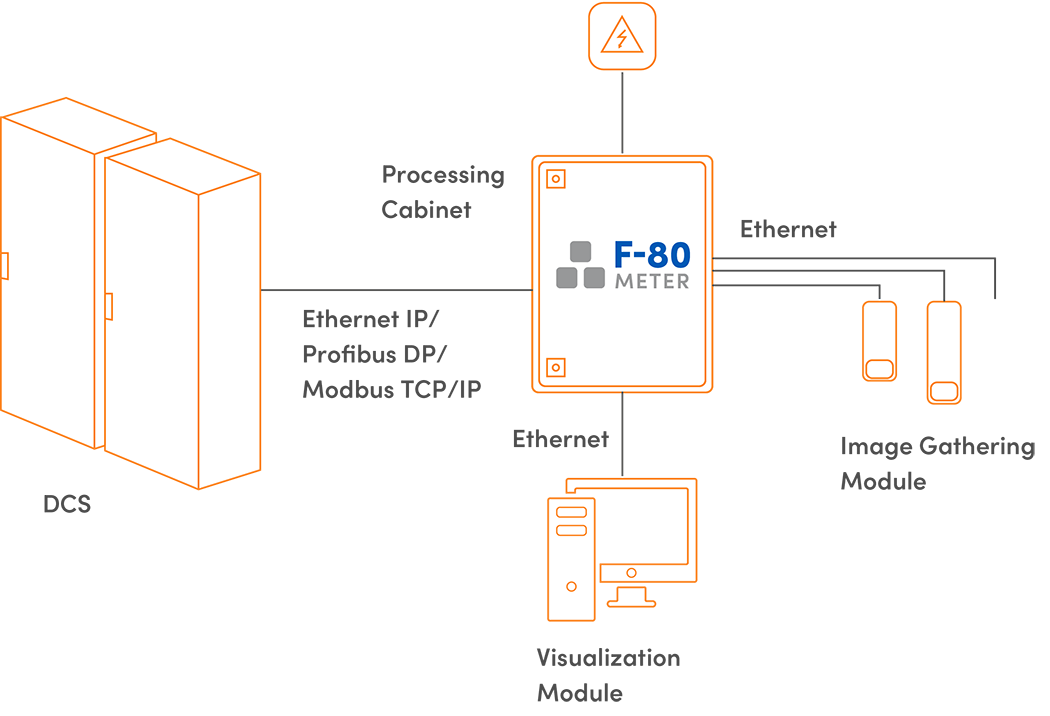

Arquitectura del sistema

F80 Meter utiliza una cámara para la segmentación de roca, una cámara para la volumetría y la iluminación industrial instalados en la parte superior de la banda para adquirir las imágenes con la mejor resolución posible.

Estas imágenes se envían al gabinete de procesamiento donde son procesadas y analizadas, posteriormente se envían al DCS mediante la comunicación industrial Ethernet IP, Profibus DP, Modbus TCP/IP. El módulo de visualización avanzada se enlaza con el modulo de procesamiento mediante Ethernet IP.

Beneficios del Sistema: