INDUSTRIAS ALIMENTOS Y BEBIDAS

INDUSTRIAS ALIMENTOS Y BEBIDAS

Cerveza artesanal.

Solución para incrementar la eficiencia de la producción.

El principal reto en una casa de cocimientos es producir la cerveza con la mejor calidad y cumplir las expectativas de los clientes. Existen varios retos para poder tener un proceso rentable y productivo que cumpla con la calidad y al mismo tiempo reduzca costos y tiempos de producción. Para construir una mejor cervecería se requiere de un sistema flexible que permita visualizar su proceso.

ECN Automation como Solution Partner de Rockwell Automation cuenta con la capacitación y experiencia del proceso necesario para la implementación de FactoryTalk Craft Brew, una solución de automatización que permite mejorar la eficiencia de su planta fácil de usar, a un precio competitivo que facilita la rastreabilidad del proceso y promueve la repetibilidad del mismo.

Beneficios

Caso de Éxito

01

Cervecera artesanal

Objetivo:

Migración del sistema de control con plataforma Siemens S5 de la casa de elaboración, e integrar un sistema de control renovado de Rockwell Automation con un procesador ControlLogix L7, la solución se basa en integrar un nuevo controlador en el gabinete CC1 con la capacidad para soportar las señales de campo con las que se cuenta actualmente, para alojar el nuevo sistema de control se considera reutilizar el tablero de control existente.

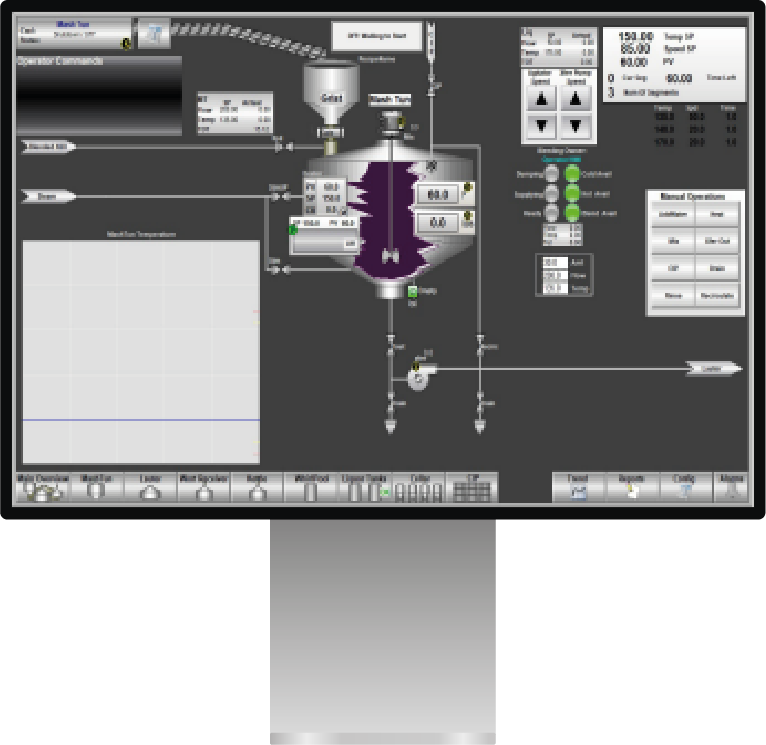

Para la parte de visualización se propone colocar una estación de operación (Workstation) con 2 pantallas de 32” para visualización de overview de proceso y la segunda para poder observar y controlar a detalle el proceso.

ALCANCE:

BENEFICIOS: