INDUSTRIAS CUIDADO DE LA SALUD PROCESOS

INDUSTRIAS CUIDADO DE LA SALUD PROCESOS

Cuidado personal

La industria del cuidado personal esta referida a lo producción de aquellos productos de consumo necesarios para tu aseo e higiene, artículos de belleza, tocador, perfumes y aspecto personal.

La producción de artículos de cuidado personal al ser una industria de consumo requiere sistemas de producción masiva que cumplan con los requisitos y formulaciones de cada producto, para cumplir la calidad y la estandarización, así como la eficiencia de los procesos es necesario la implementación de sistemas de instrumentación, automatización e información diseñados a la medida de cada proceso.

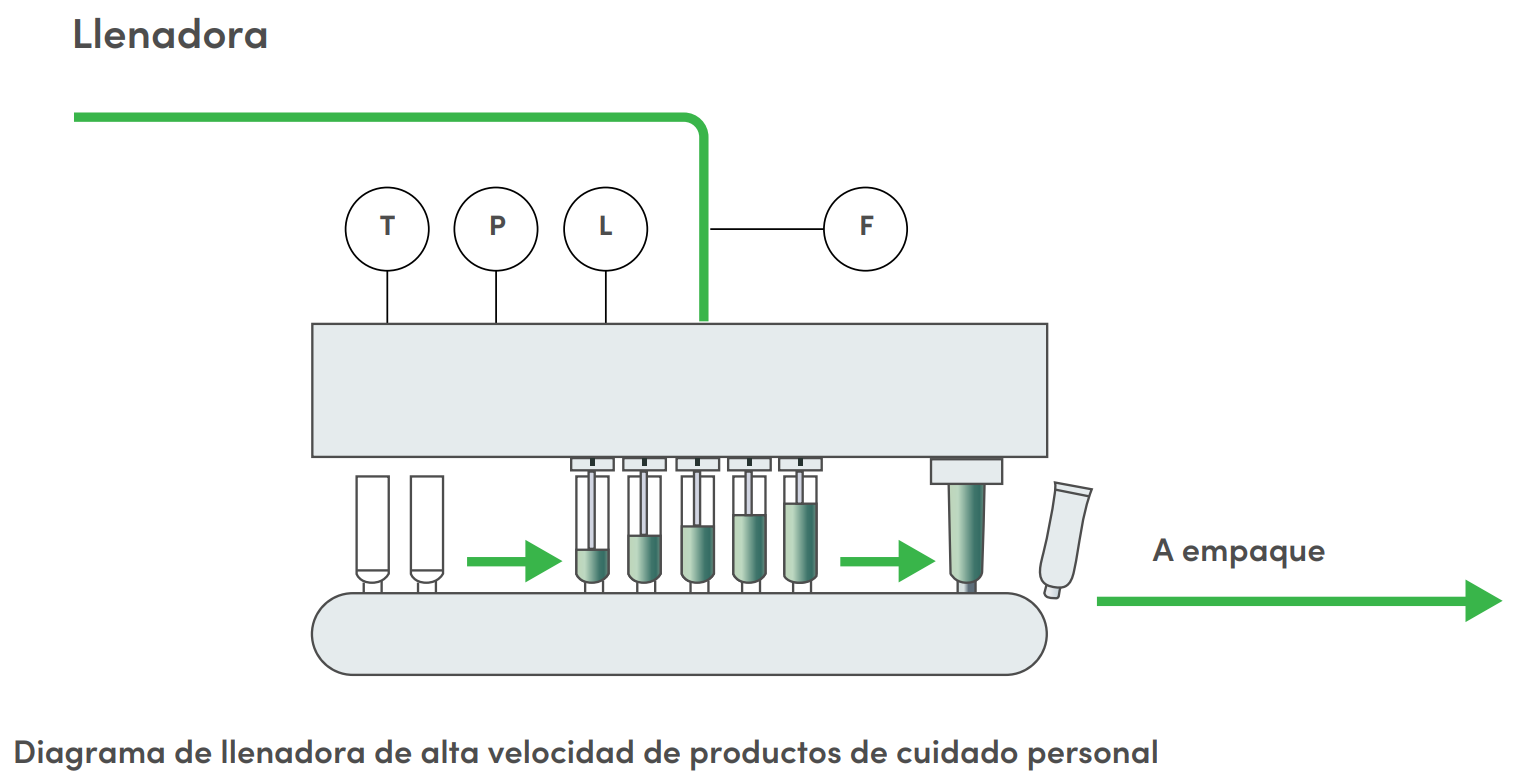

Dosificación y llenado continuo con alta precisión

Asegurar que la cantidad exacta de producto se llena cada vez de manera precisa y continua es indispensable en el proceso de producción de cosméticos. Además, los componentes de llenado y dosificación mecánicos pueden soportar altos costes de mantenimiento y ser poco fiables, lo que desencadena interrupciones prolongadas del proceso.

Los sistemas automáticos mejoran la calidad del producto y se vita la manipulación por parte del operario, evitando contaminación del producto, así como se dispense siempre la misma cantidad.

Aumento en la producción, se reducen tiempos muertos en el proceso y la posibilidad de crecer aún mas con la integración de nuevos sistemas de llenado.

Esto sistemas aplica para los productos:

Eliminación de impurezas en pasta papel

El agua ya espesada es alimentada hacia una prensa desaguadora donde su contenido de solidos aumenta hasta un 32% posteriormente es llevado a un túnel que mediante un sistema de inyección de vapor se eleva su temperatura para hacerlo pasar por los discos de dispersión donde se le adiciona licor de blanqueo antes de ser enviado a la torre de blanqueo.

Diagrama proceso de: eliminación de impurezas en pasta de papel

Blanqueo de pulpa

Para obtener el nivel de blancura deseado, se debe blanquear la pulpa. Para ello, se introduce en una torre de blanqueo de hasta 25 m de altura. El proceso de blanqueo se desarrolla de forma continua en temperaturas de hasta +95 °C con la adición de productos químicos para el blanqueo como oxígeno, ozono, peróxido de hidrogeno e hidróxido de cloro. Todo este proceso se debe de hacer antes de ser enviado al sacador.

Diagrama proceso de: blanqueo de pulpa para producción de papel sanitario

Para obtener el nivel de blancura deseado, se debe blanquear la pulpa. Para ello, se introduce en una torre de blanqueo de hasta 25 m de altura. El proceso de blanqueo se desarrolla de forma continua en temperaturas de hasta +95 °C con la adición de productos químicos para el blanqueo como oxígeno, ozono, peróxido de hidrogeno e hidróxido de cloro. La celulosa final ya blanqueada se descarga mediante sinfines. Debido a su tamaño, la torre de blanqueo no se vacía nunca. Una medición de nivel continua permite garantizar un proceso sin problemas.

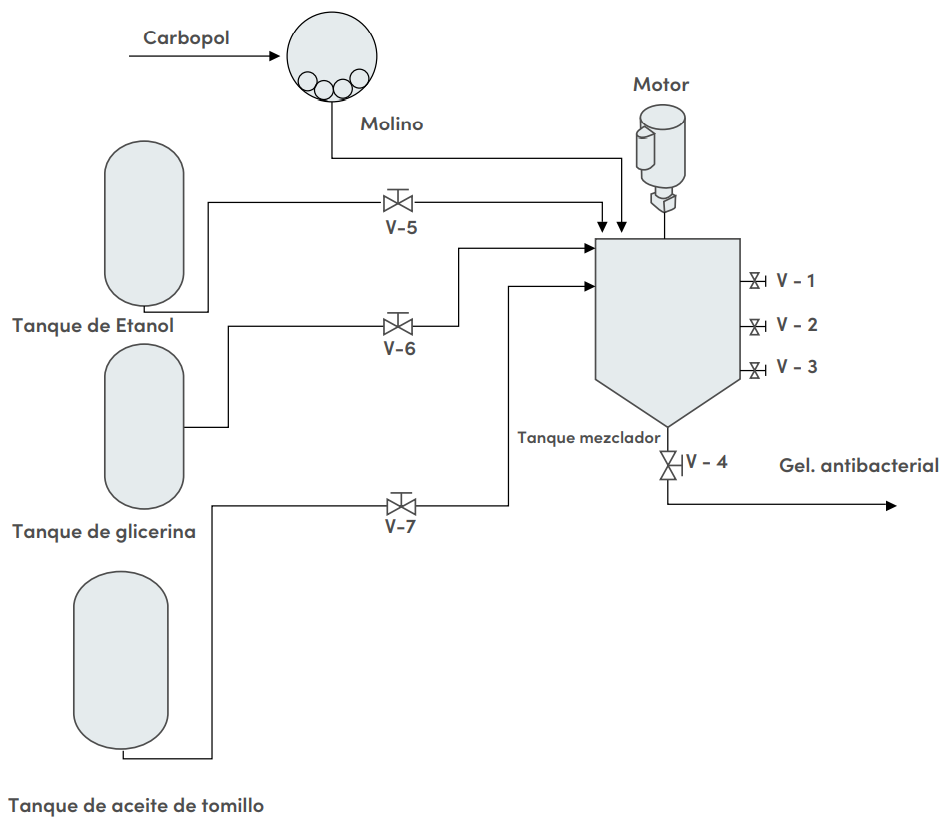

Elaboración de Gel Antibacterial

Reduce significativamente la cantidad de bacterias que se encuentran en las manos. Como no siempre se dispone de jabón y agua para la limpieza de las manos el usar el alcohol contenido en un gel que pueda ser fácilmente aplicado y transportado representa una buena opción para lograr una desinsectación constante y eficiente.

El proceso consiste en la correcta dosificación y secuencia si como el tiempo y perfecta mezcla de los componentes en el tranque agitador para llegar a la correcta viscosidad.

Diagrama proceso de: molienda del Carbopol y el mezclado de todas las sustancias.