AUTOMATIZACION DE PROCESOS PLATAFORMA ROCKWELL

AUTOMATIZACION DE PROCESOS PLATAFORMA ROCKWELL

Sistema de control distribuido DCS

Rockwell DCS PlantPAx

El sistema PlantPAx© utiliza una plataforma de automatización común para facilitar la integración transparente entre las zonas de procesos críticas y el resto de su planta. Conecta el control de procesos, discreto, de alimentación, de información y de seguridad en una sola infraestructura a nivel de toda la planta que aumenta la eficiencia y la productividad en todos los niveles de sus operaciones.

En ECN Automation contamos con ingenieros certificados para especificar e implementación de PlantPAx, realizando más de 30 proyectos en diferentes industrias, usando las mejores prácticas en diseño y desarrollo que aseguran el mejor resultado en desempeño.

Características del DCS PlantPAx

Ofrece una amplia gama de opciones de arquitectura que aumentan la flexibilidad. Se puede utilizar la misma plataforma para estaciones individuales o para grandes arquitecturas distribuidas. El DCS PlantPAx se basa en estándares de comunicación abiertos y protegidos que emplean EtherNet/ IP como conexión principal.

Con un sistema de control distribuido garantizamos:

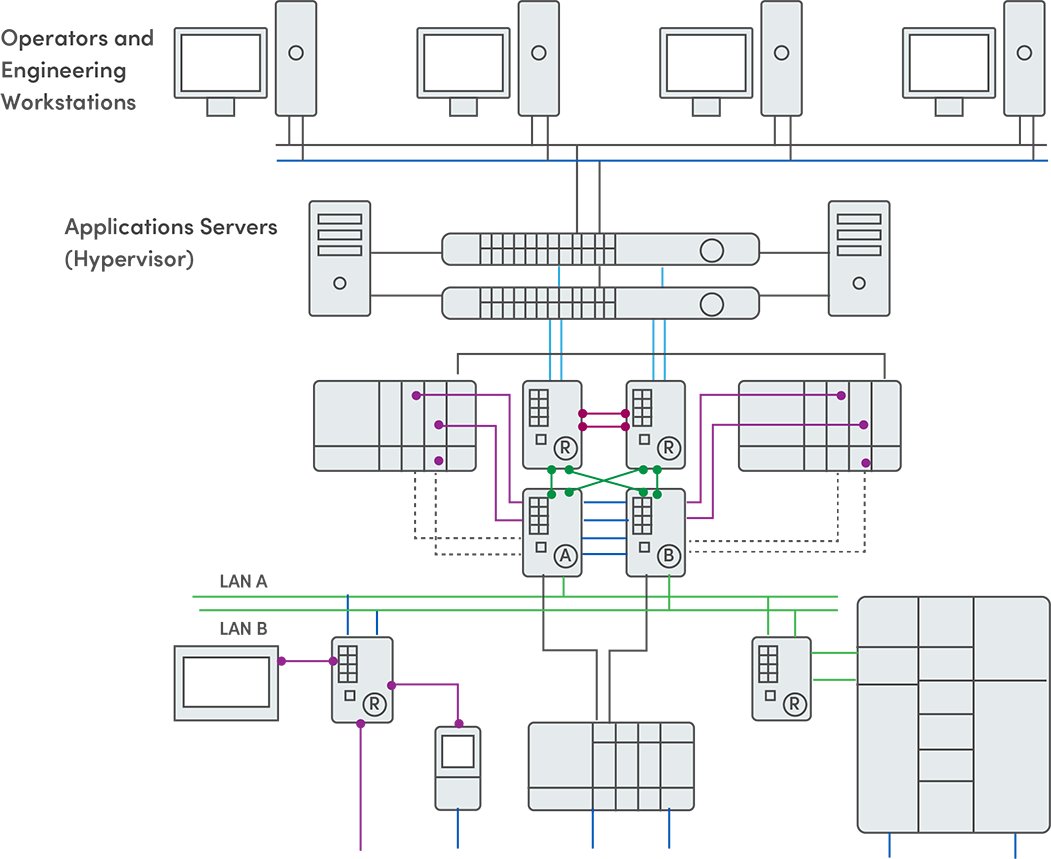

Arquitectura PlantPAx

Configuraciones DCS PlantPAx:

Configuración sencilla:

Consiste en un DCS con un solo PAC conectado por Ethernet IP con los nodos de I/O para reconexión de datos.

Varios PAC´s:

Consiste en tener varios controladores en diferentes chasises a lo largo de la planta, conectados entre sí y con los nodos de I/O´s.

Alta disponibilidad:

Para tener alta disponibilidad se requiere garantizar que los equipos activos de control estén más del 99.9% disponibles para operar, una de las principales características es la redundancia incorporada a todos los niveles, desde las E/S hasta los controladores, las redes y los servidores.

Arquitectura Integrada:

Independientemente de las configuraciones anteriormente mencionadas, la arquitectura integrada es cuando los dispositivos de campo como CCM´s, instrumentos y actuadores utilizan el protocolo de comunicación ethernet para conectarse con el PAC obteniendo mayor información y facilidad de acceso.

Beneficios de la implementación de PlantPAx

ECN Automation con 30 años de experiencia en la industria de proceso tiene un equipo de ingenieros capacitados de acuerdo al programa Rockwell PlantPAx para realizar la implementación exitosa del mismo; obteniendo los mejores resultados para la operación productiva y segura de su planta en un tiempo de desarrollo ágil.

Certificado a personal para aplicación de PlantPAx